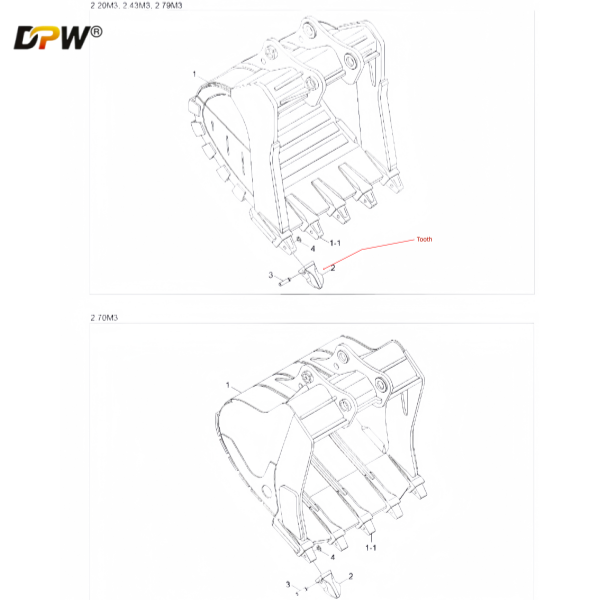

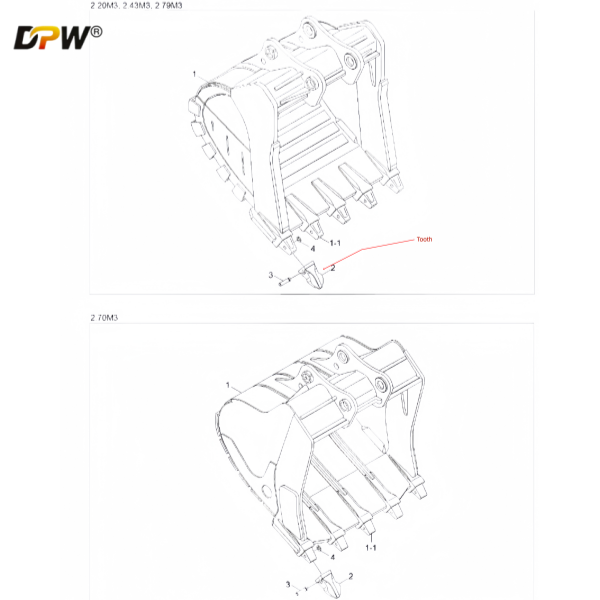

HYUNDAI 61QB31310 R480/R520/HX520 piont tooth - Design for mines original supplier-HAN GONG / DPW PARTS

Product Specifications

HYUNDAI R480/R520/HX520 Point Tooth (61QB31310): Mining-Optimized Design by HAN GONG / DPW PARTS

Executive Overview

HAN GONG / DPW PARTS, an original supplier specializing in mining-grade wear components, presents its engineered Point Tooth for HYUNDAI R480, R520, and HX520 series excavators (Part Number: 61QB31310). This product is specifically designed for mines, incorporating advanced forging technology and material science to deliver exceptional penetration, wear resistance, and structural reliability in the most severe abrasive and high-impact environments.

1. Product Identification & Target Application

1.1 Core Function in Mining Operations

The point tooth is the primary digging and rock-breaking tool on an excavator bucket. In mining applications, its performance dictates:

Penetration Force: Concentrated point geometry for breaking into hard, compacted, and rocky overburden with maximum efficiency.

Abrasion Management: Engineered to withstand continuous abrasion from ore, taconite, and abrasive strata.

Impact Resistance: Built to absorb shock loads from encountering large, unyielding rock formations without fracture.

Productivity Link: Directly influences cycle times, fuel efficiency, and total material moved per shift.

1.2 Machine Compatibility

Primary Application: HYUNDAI R480LC-9A, R520LC-9A Mining & Quarry Excavators.

Compatible Application: HYUNDAI HX520L Mining Excavator.

Adapter System: Designed for seamless integration with the corresponding HYUNDAI adapter (e.g., system compatible with 61QB series).

OEM Reference: Direct replacement for HYUNDAI part number 61QB31310.

2. Mining-Focused Design & Forging Manufacturing

For mining applications, standard cast teeth are insufficient. HAN GONG / DPW PARTS employs a precision hot-forging process to create a product that meets the extreme demands of 24/7 mining operations.

2.1 The Precision Forging Process for Mining

Special Alloy Selection: Use of premium boron-chromium alloy steel, formulated for an optimal balance of high hardness and exceptional toughness—a critical requirement for mining where both severe abrasion and impact are present.

Hot Die Forging: The steel is forged under extreme pressure, creating a unidirectional grain flow that follows the tooth contour. This eliminates the isotropic weaknesses of castings and provides superior fatigue strength.

Controlled Quenching & Tempering: A multi-stage heat treatment creates a differential hardness profile. The tip and leading edges achieve very high hardness (48-52 HRC) for wear resistance, while the core and root maintain lower hardness (38-42 HRC) for shock absorption and to prevent brittle fracture.

Precision Machining: The lock mechanism interface and bore are CNC-machined to ensure a perfect, secure fit with the adapter. This prevents premature wear caused by movement and ensures all digging force is transmitted effectively.

Quality Verification: Rigorous testing includes spectral analysis, batch hardness mapping, and dimensional inspection using templates and calipers to guarantee consistency and conformity.

2.2 Design Features for Mining Efficiency

Aggressive Point Geometry: The profile is optimized to reduce cutting resistance in dense materials, promoting faster bucket filling and lower hydraulic strain.

Reinforced Stress Zones: Additional material is strategically placed in high-wear areas (tip, sides) and high-stress areas (locking groove, transition to shank) to extend life and prevent breakage.

Secure Locking Design: Precision-machined locking interface ensures the tooth remains firmly seated, protecting the adapter from wear and preventing tooth loss.

3. Technical Specifications

3.1 Material & Metallurgy

Material Grade: High-strength, low-alloy (HSLA) forging steel with Boron and Chromium additives.

Hardness Profile: Surface hardness: 48-52 HRC; Core hardness: 38-42 HRC.

Microstructure: Fine, tempered martensitic structure ensuring both strength and ductility.

4. HAN GONG / DPW PARTS: Capabilities as an Original Supplier for Mining

Our role as an original supplier entails full vertical integration and application-specific expertise:

Mine-Specific R&D: Product development focused on solving the unique wear challenges of coal, iron ore, copper, and aggregate mining.

End-to-End Manufacturing: Complete in-house control over forging, heat treatment, machining, and quality assurance ensures traceability and reliability.

Quality Management System: Adherence to international standards (ISO 9001) with protocols for raw material certification, in-process inspection, and final audit.

Performance Testing: Components are tested under simulated mining conditions to validate wear life and impact resistance.

Global Logistics through DPW PARTS: Robust supply chain network ensures timely delivery to mining operations worldwide.

5. Value Proposition for Mining Operations

For mine managers, the economic equation centers on cost per ton (CPT):

Extended Wear Life: Superior forged material and mining-optimized design directly extend replacement intervals, reducing the number of teeth consumed per million tons of material.

Maximized Machine Availability: Reduced frequency of tooth changes means more productive machine hours and less downtime for maintenance.

Protection of Capital Components: A secure-fitting, high-quality tooth protects the adapter and bucket lip from accelerated wear, avoiding far more costly structural repairs or replacements.

Optimized Digging Performance: Maintains sharp penetration and efficient bucket fill factors longer, supporting consistent cycle times and lower fuel consumption per ton.

Lower Total Operating Cost: The combination of longer service life, reduced downtime, and protected bucket integrity delivers the lowest possible cost per ton of material excavated.