Caterpillar-D9N/R/T-Segment/7T1247/Heavy duty CAT Machine undercarriages spare parts source manufacture and supplier factory

Product Specifications

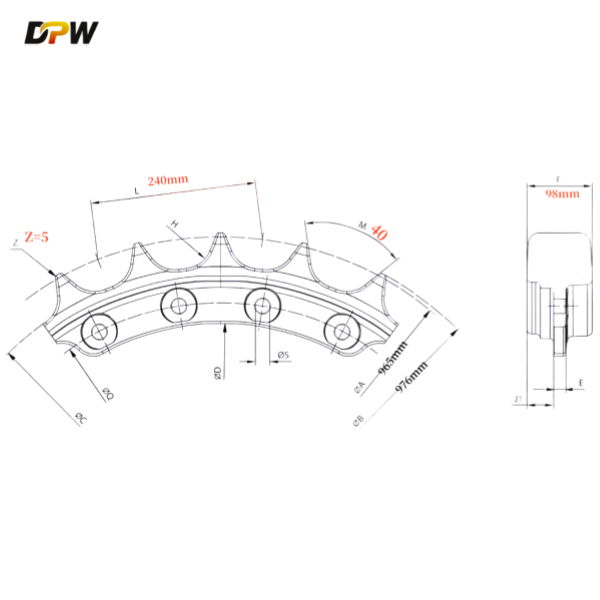

Caterpillar D9N/R/T Track Sprocket Segment: Technical Specifications & Functional Analysis

Optimized for Heavy-Duty Undercarriage Performance, Global Interchangeability & Mining-Grade Durability

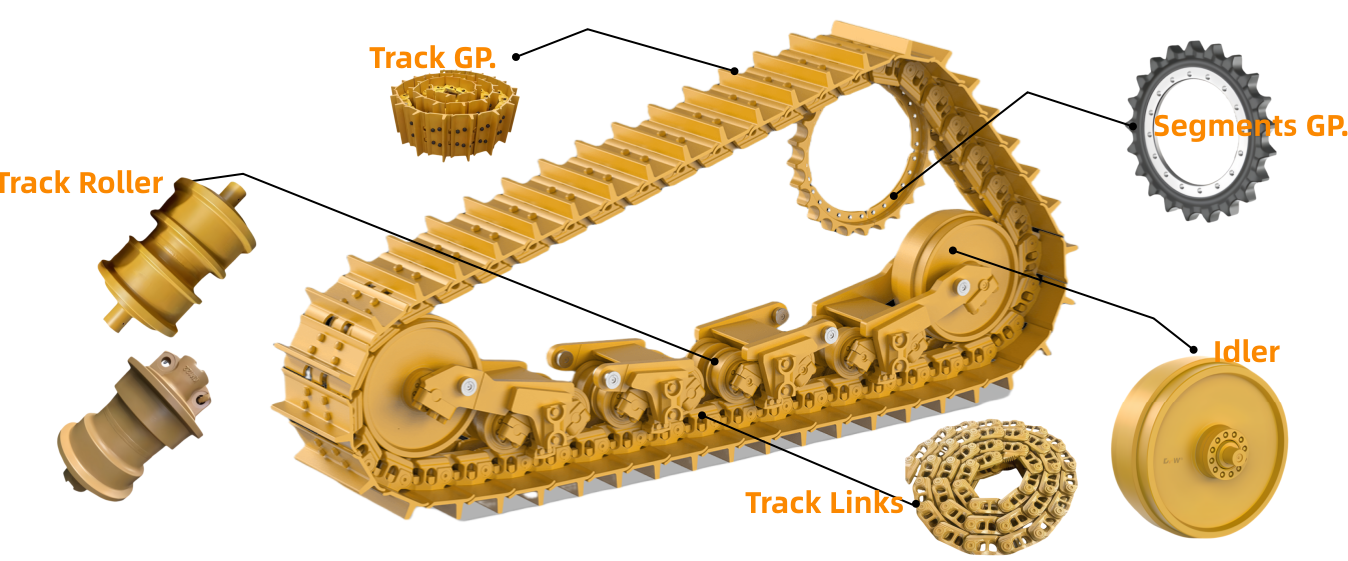

The Cat-D9R track Sprocket segment (commonly termed track shoe or track link assembly) is a critical undercarriage component in Caterpillar D9-series track-type tractors, engineered to transmit drive torque, distribute ground pressure, and withstand extreme abrasion in mining, quarrying, and heavy earthmoving operations. Its design directly impacts machine traction, fuel efficiency, and undercarriage service life .

1. Core Function & System Integration

Primary Role:

Transfers propulsion force from the final drive sprocket to the terrain via interlocked track pads .

Distributes machine weight (D9R: 49+ tons) to reduce ground pressure (<100 kPa) .

Interfaces with track rollers (e.g., P/N 381-4191) and idlers to maintain track tension .

Load Dynamics:

Peak tensile strength: 1,200+ kN to resist chain stretching under load .

Impact resistance: Absorbs shock loads during sidehill operation or rock strikes .

2. Technical Specifications & Material Science

| Parameter | Specification |

|---|---|

| Compatibility | D9N, D9R, D9T, D9RLRC, MD6290 series |

| OEM Part Number | 142-5867 (Seal), 7X-0420 (Bolt) |

| Segment Weight | 120–150 kg (varies by shoe width) |

| Material Composition | Forged 35MnB alloy steel |

| Hardness | HRC 52–58 (surface); depth: 8–12 mm |

| Pin/Bush Diameter | 50.8 mm ±0.05 mm |

| Bolt Torque Spec | 115 ±20 N·m (for 7X-0420 bolts) |

3. Structural Breakdown & Manufacturing

Track Shoe Plate:

Design: Single-grouser or multi-grouser configurations for rock/soft terrain .

Process: Hot forging + induction hardening to minimize wear rates (<0.5 mm/1,000 hrs) .

Track Link & Bush Assembly:

Bush: Case-hardened 20CrMnTi steel; installed via interference fit (0.15–0.25 mm) .

Seal System: Triple-lip + labyrinth seals (e.g., P/N 1425867) validated for submersion .

Connecting Components:

Pins: Carburized 18CrNiMo7-6 steel; taper-ground to 1:50 ratio .

Bolts: ISO 10.9-grade high-tensile steel (e.g., 7X-0420) with anti-corrosion coating .

4. Failure Modes & Maintenance Protocol

Common Failure Symptoms:

Grouser wear >40% height: Causes loss of traction and increased slippage .

Bush ovalization (>2 mm): Leads to chain pitch elongation and sprocket jump-off .

Seal leakage: Contaminates lubricant with grit, accelerating bearing wear .

Service Life:

Standard: 6,000–8,000 hrs (rock applications reduce lifespan by 30%) .

Preventive Maintenance:

Biweekly: Measure chain pitch elongation (replace if >3% of original).

Quarterly: Inspect seal integrity using dye penetrant tests .

Annual: Replace segment groups in matched sets to prevent uneven stress .

5. Global Procurement & Sourcing Guide

| Source Type | Key Suppliers | Regional Logistics |

|---|---|---|

| OEM (Caterpillar) | - Part Number: 142-5867 (seal), 7X-0420 (bolt) - Verification: Cat® SIS 2.0 portal or AR scanning via Cat®Parts app - Warranty: 12 months global coverage | NA/EU: 3–5 days (dealer stock) APAC: 7–10 days (Singapore hub) |

| Aftermarket | - Fujian Quanyu (China): ISO 9001-certified 35MnB forgings; MOQ: 20' container - Reliable Aftermarket Parts (USA): eBay seller; ships seals/bolts globally (30-day returns) | FOB China: $120–$150/segment USA: $48.99/seal (eBay) |

6. Compatibility & Anti-Counterfeiting Measures

Model-Specific Validation:

Confirm D9N vs. D9T suffix alignment; D9R Phase III uses updated bush profiles .

Cross-reference via equipment serial number on Cat® SIS 2.0 .

Genuine Part Identification:

Laser-etched 12-digit security codes + QR traceability (post-2024 parts) .

Demand material certs (EN 10204 3.1) for aftermarket purchases