CATERPILLAR E390 Sprocket assembly(P/N:639-7792) for heavy duty excavator undercarriage parts made by DPW parts machinery

Product Specifications

Key Functions of the CATERPILLAR-E390 Final Drive Sprocket:

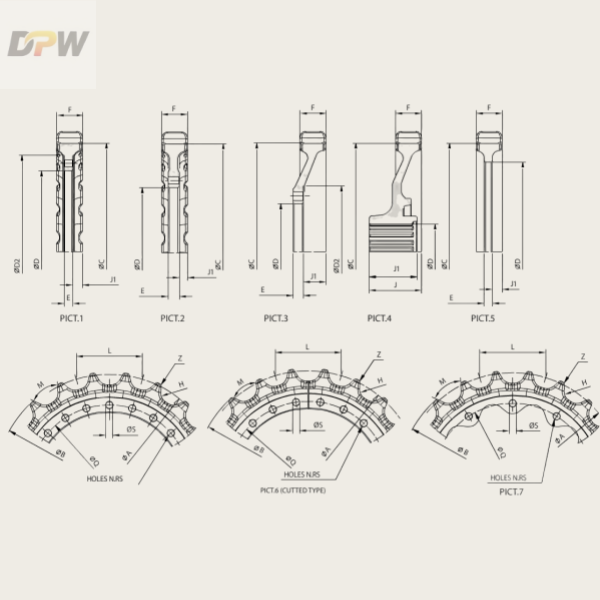

Power Transmission – Receives rotational force from the final drive assembly (which is connected to the transmission) and transfers it to the tracks.

Track Engagement – The teeth of the sprocket mesh with the track links, pulling the track chain in a continuous loop.

Load Distribution – Supports the weight of the machine and distributes forces evenly across the track system.

Durability & Wear Resistance – Made from hardened steel to withstand high stress, abrasion, and impact.

Common Issues & Maintenance:

Wear & Tear – Teeth can wear down over time, leading to poor track engagement and slippage.

Misalignment – Can cause uneven wear on tracks and sprockets.

Lubrication Failure – Final drive sprockets are often part of a sealed, lubricated final drive unit; leaks or contamination can lead to premature failure.

Replacement Signs:

Excessive track slippage

Visible damage or missing sprocket teeth

Unusual grinding noises from the track system

Proper maintenance and timely replacement ensure optimal power transfer, fuel efficiency, and longevity of the undercarriage system.