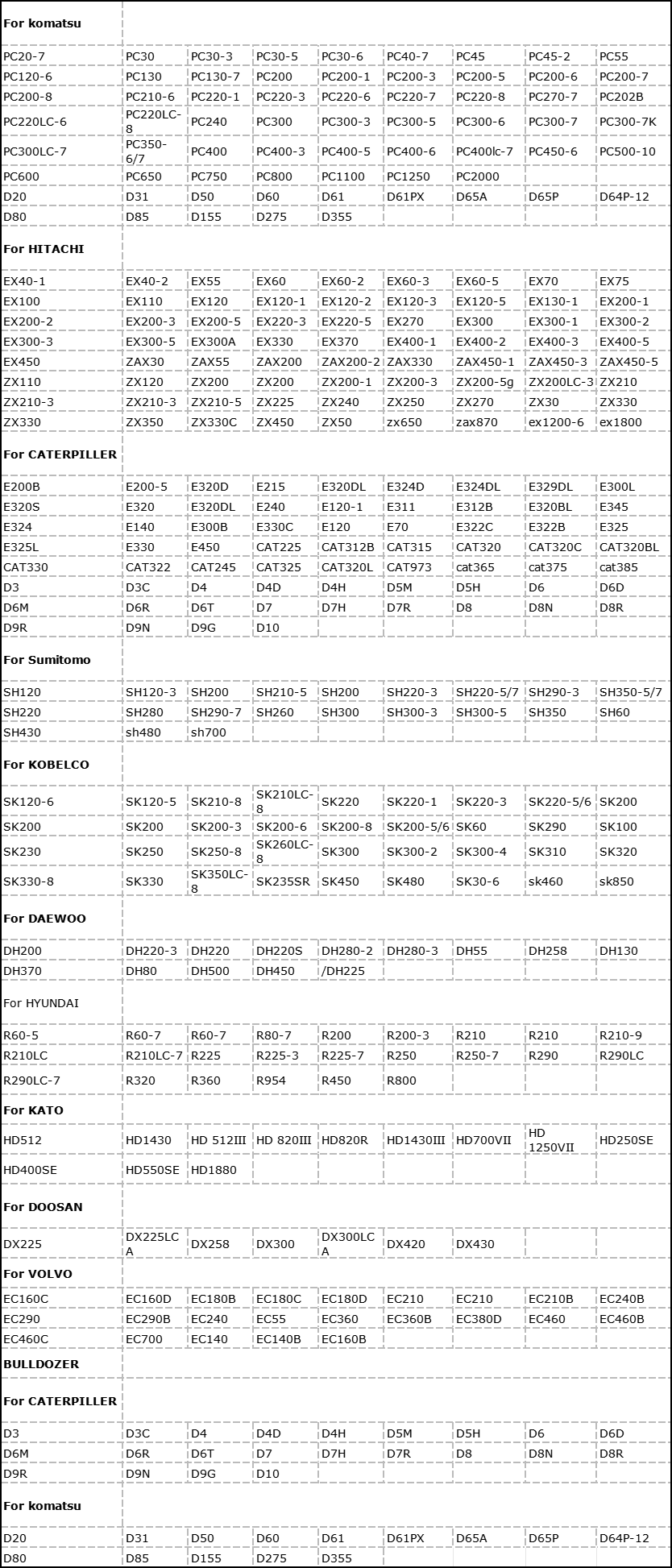

CATERPILLAR E320/MD5150C track roller/8E5032/1634143/CR5572/993597/excavator undercarriage part OEM quality track roller source factory

Product Specifications

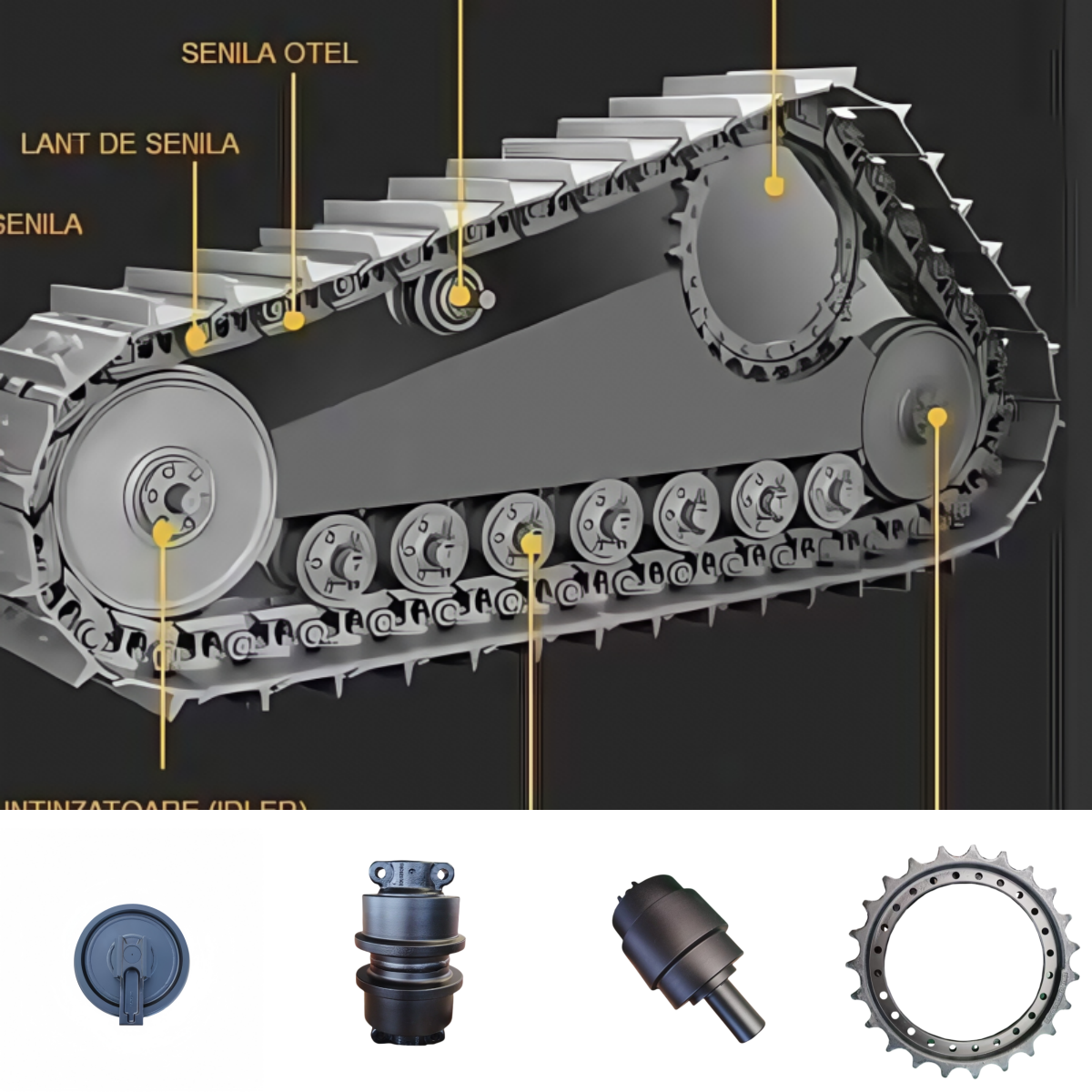

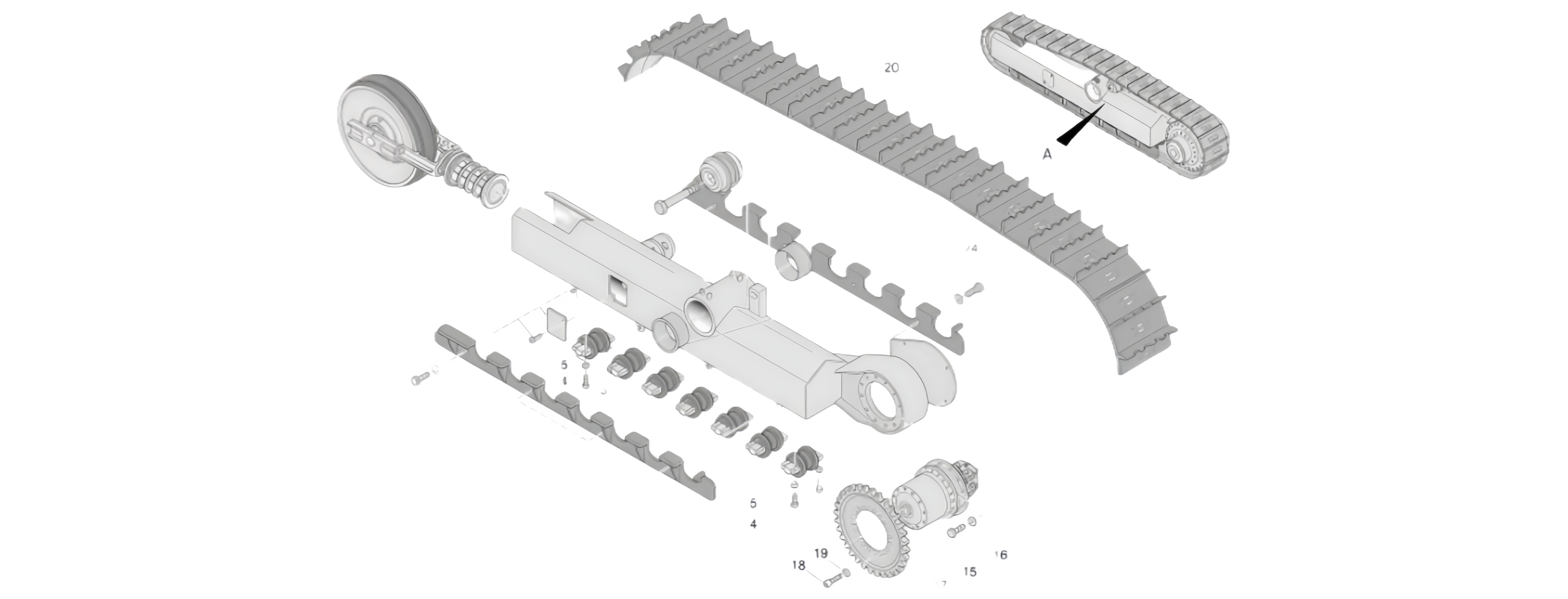

Cat® E320 Track Bottom Roller Assembly is a critical load-bearing component within the undercarriage system of the Cat® E320 hydraulic excavator. Engineered to support the machine's operating weight and guide the track chain, this roller ensures smooth operation, maintains track alignment, and absorbs ground-level impacts in the most severe working conditions.

Key Features & Technical Specifications

Compatibility & Identification

Machine Models: Specifically designed for Cat® E320 series excavators

Application: Lower track frame support between front idler and sprocket

OEM Quality: Guaranteed fit and performance with genuine Cat® specifications

Construction & Materials

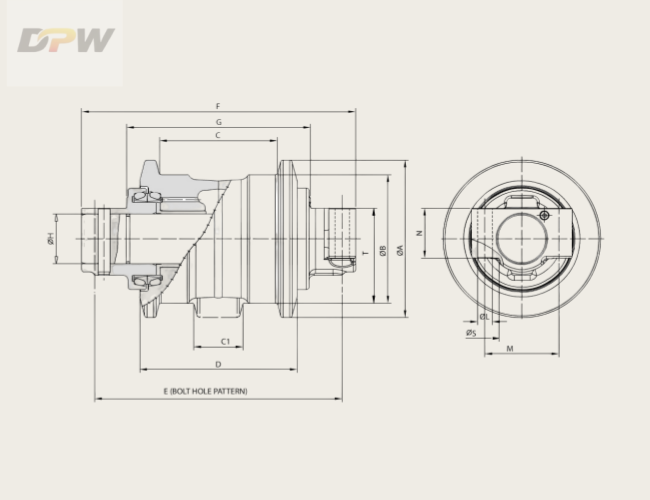

Forged Steel Construction: Superior impact resistance compared to cast alternatives

Induction-Hardened Tread: Surface hardness of 55-60 HRC for extreme abrasion resistance

Precision Machining: Critical surfaces machined to exact tolerances for optimal performance

Double Flange Design: Integral flanges for track guidance and derailment prevention

Bearing & Sealing System

Tapered Roller Bearings: Heavy-duty design for extreme radial load capacity

Cat® Duo-Cone Seals: Advanced sealing technology for superior contaminant exclusion

Lube-for-Life Design: Factory pre-lubricated for maintenance-free operation

Pre-loaded Bearings: Optimized for smooth operation and extended service life

Performance Specifications

Load Capacity: Designed for E320 operating weights and dynamic loads

Wear Resistance: Hardened surfaces provide extended service life

Temperature Range: Operational from -40°C to 50°C (-40°F to 122°F)

Sealing Effectiveness: Tested against fine abrasives and moisture intrusion

Compatibility & Identification

Machine Models: Specifically designed for Cat® E320 series excavators

Application: Lower track frame support between front idler and sprocket

OEM Quality: Guaranteed fit and performance with genuine Cat® specifications

Construction & Materials

Forged Steel Construction: Superior impact resistance compared to cast alternatives

Induction-Hardened Tread: Surface hardness of 55-60 HRC for extreme abrasion resistance

Precision Machining: Critical surfaces machined to exact tolerances for optimal performance

Double Flange Design: Integral flanges for track guidance and derailment prevention

Bearing & Sealing System

Tapered Roller Bearings: Heavy-duty design for extreme radial load capacity

Cat® Duo-Cone Seals: Advanced sealing technology for superior contaminant exclusion

Lube-for-Life Design: Factory pre-lubricated for maintenance-free operation

Pre-loaded Bearings: Optimized for smooth operation and extended service life

Performance Specifications

Load Capacity: Designed for E320 operating weights and dynamic loads

Wear Resistance: Hardened surfaces provide extended service life

Temperature Range: Operational from -40°C to 50°C (-40°F to 122°F)

Sealing Effectiveness: Tested against fine abrasives and moisture intrusion

Applications

Excavation Work: Trenching, digging, and material handling

Construction Sites: Building foundations and site preparation

Demolition Projects: Building demolition and material processing

Quarry Operations: Rock digging and material loading

Excavation Work: Trenching, digging, and material handling

Construction Sites: Building foundations and site preparation

Demolition Projects: Building demolition and material processing

Quarry Operations: Rock digging and material loading

Benefits of Genuine Cat® Replacement

Extended Service Life: Premium materials and hardening processes reduce wear rates

Reduced Downtime: Precision manufacturing ensures reliable performance

Optimal Fitment: Guaranteed compatibility with E320 undercarriage system

Warranty Protection: Backed by Cat® warranty and support services

Balanced Wear: Promotes even wear across entire undercarriage system

Extended Service Life: Premium materials and hardening processes reduce wear rates

Reduced Downtime: Precision manufacturing ensures reliable performance

Optimal Fitment: Guaranteed compatibility with E320 undercarriage system

Warranty Protection: Backed by Cat® warranty and support services

Balanced Wear: Promotes even wear across entire undercarriage system

Maintenance Recommendations

Regular Inspection: Check for wear patterns and seal integrity every 250 hours

Proper Cleaning: Remove packed material to prevent seal damage

Track Tension: Maintain proper track tension according to operator's manual

Replacement: Replace in sets for balanced undercarriage performance

Regular Inspection: Check for wear patterns and seal integrity every 250 hours

Proper Cleaning: Remove packed material to prevent seal damage

Track Tension: Maintain proper track tension according to operator's manual

Replacement: Replace in sets for balanced undercarriage performance

Technical Specifications Table

Parameter Specification Compatibility Cat® E320 Excavator Construction Forged Steel Surface Hardness 55-60 HRC Bearing Type Tapered Roller Seal Type Cat® Duo-Cone Lubrication Factory Pre-lubricated Flange Design Double Integral

| Parameter | Specification |

|---|---|

| Compatibility | Cat® E320 Excavator |

| Construction | Forged Steel |

| Surface Hardness | 55-60 HRC |

| Bearing Type | Tapered Roller |

| Seal Type | Cat® Duo-Cone |

| Lubrication | Factory Pre-lubricated |

| Flange Design | Double Integral |

Conclusion

The Cat® E320 Track Bottom Roller Assembly exemplifies Caterpillar's commitment to durability and performance. With its forged construction, advanced sealing system, and precision engineering, this component delivers reliable service in the most demanding applications. Choosing genuine Cat® parts ensures optimal machine performance, extended component life, and maximum return on investment.

If you need the exact part number, provide your E320’s serial number or consult the Caterpillar SIS (Service Information System). Let me know if you need help with installation or troubleshooting!