CATERPILLAR DOZERS(CR4616,134-3952,6T3216)D6H/D6R idler ass'y/bulldozer idler factory in china

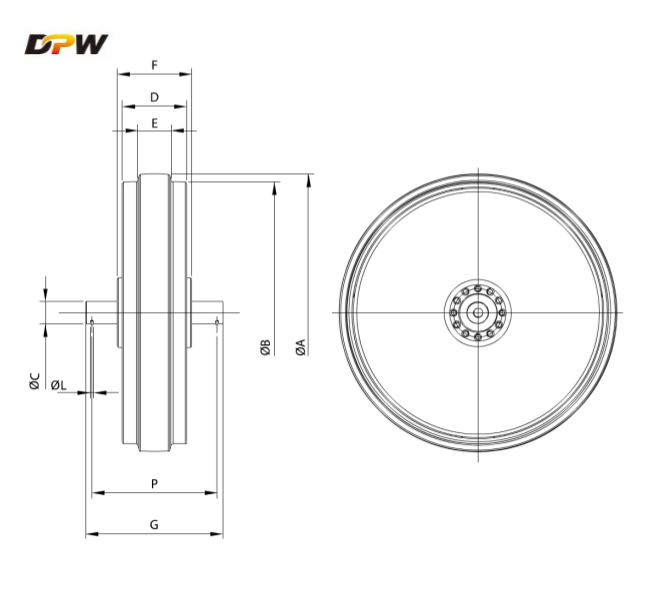

Product Specifications

CATERPILLAR DOZERS(CR4616,134-3952,6T3216)D6H/D6R forged idler ass'y.

Professional Welding & Forging Excavator Idler Wheels Source Factory | 30 Years of Welding Expertise + Advanced Robotic Welding New Forging Technology for Excavator Undercarriage Parts

Caterpillar D6R Idler Specifications

(Verify with your serial number at Cat Parts)

(Verify with your serial number at Cat Parts)

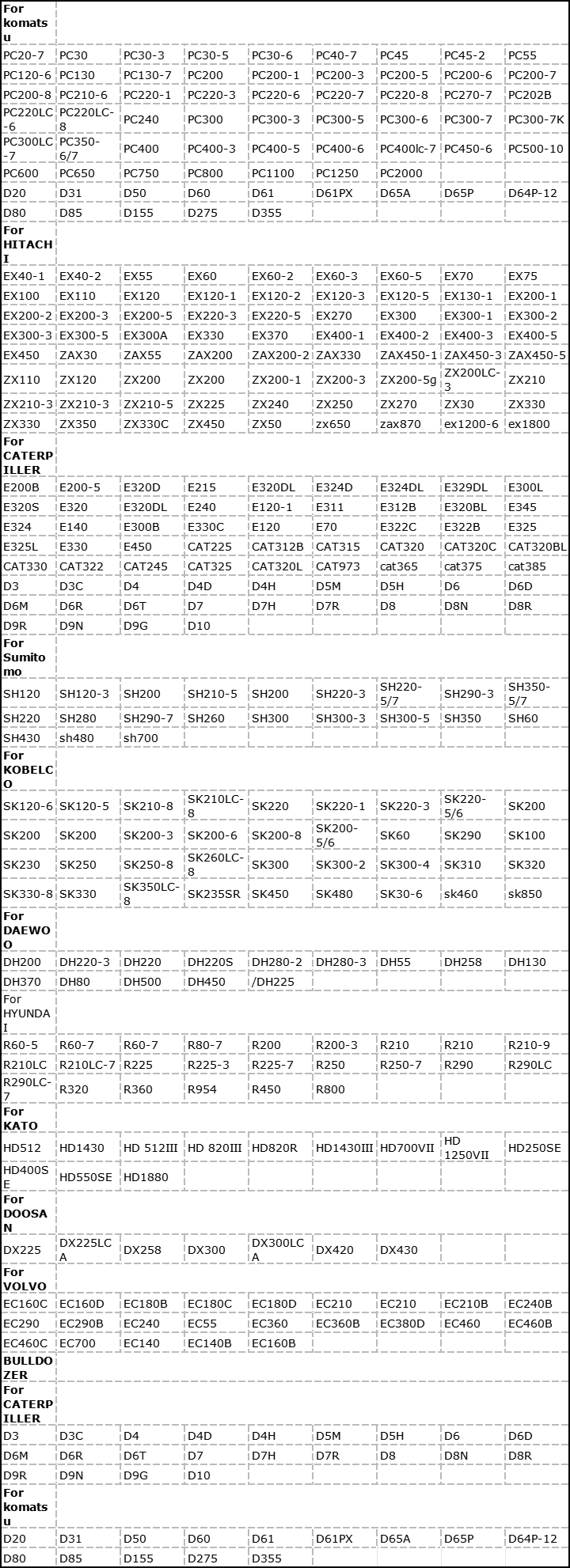

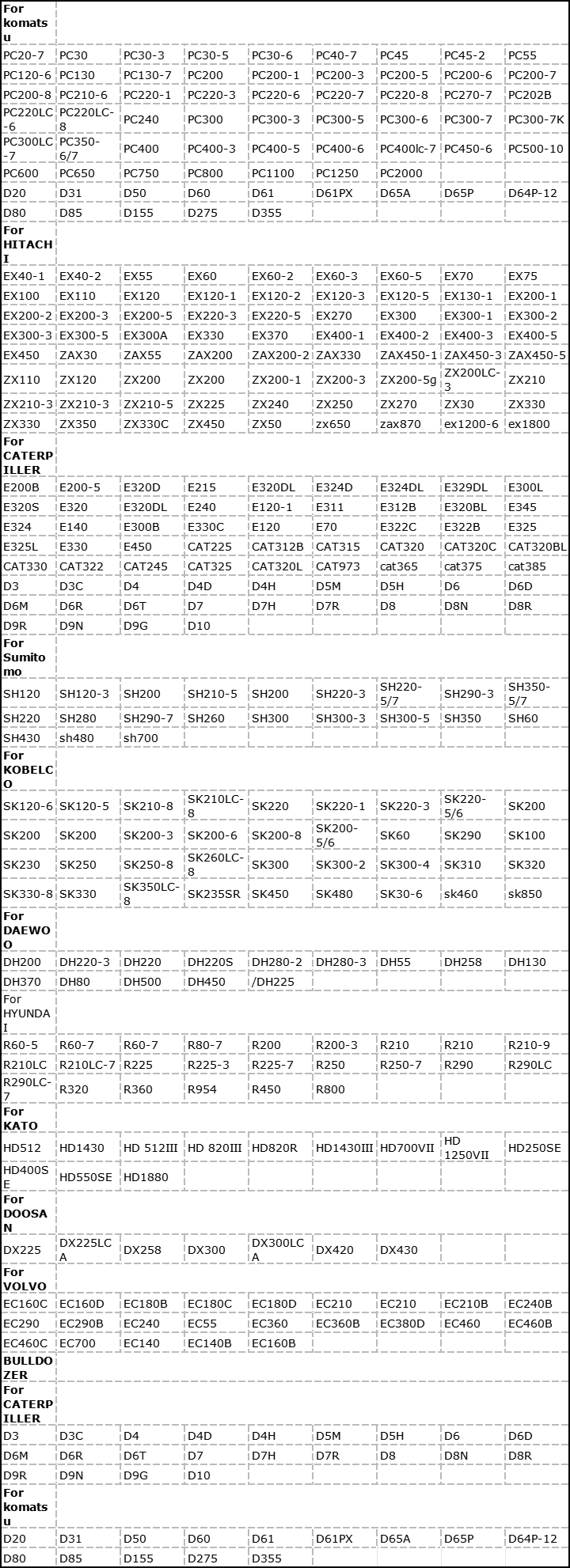

1. Model Compatibility

Applies To:

D6R Series I/II/III (XL/LGP variants included)

Compatible with some D6N/D6T models (verify dimensions)

Applies To:

D6R Series I/II/III (XL/LGP variants included)

Compatible with some D6N/D6T models (verify dimensions)

2. OEM Part Numbers

Configuration Part Number Notes Standard Front Idler 8Y-7496 600mm track gauge LGP Front Idler 242-7564 760mm wide Rebuild Kit (Seals/Bearings) 6I-5995 Includes all wear parts

| Configuration | Part Number | Notes |

|---|---|---|

| Standard Front Idler | 8Y-7496 | 600mm track gauge |

| LGP Front Idler | 242-7564 | 760mm wide |

| Rebuild Kit (Seals/Bearings) | 6I-5995 | Includes all wear parts |

3. Technical Specifications

Parameter Standard Idler LGP Idler Material Cast Steel (SAE 4320) Forged Steel (4140) Weight 220 kg 280 kg Width 520 mm 760 mm Bearing Type Tapered Roller Double Tapered Roller Grease Fittings 2 (90° opposed) 3 (120° spacing) Load Capacity 15,000 kg static 18,000 kg static

| Parameter | Standard Idler | LGP Idler |

|---|---|---|

| Material | Cast Steel (SAE 4320) | Forged Steel (4140) |

| Weight | 220 kg | 280 kg |

| Width | 520 mm | 760 mm |

| Bearing Type | Tapered Roller | Double Tapered Roller |

| Grease Fittings | 2 (90° opposed) | 3 (120° spacing) |

| Load Capacity | 15,000 kg static | 18,000 kg static |

Wear Limits & Maintenance

Flange Thickness:

New: 35 mm

Replace at: ≤18 mm

Bearing Play:

Allowable: ≤1.8 mm radial

Critical: >2.5 mm

Greasing:

Interval: Every 10 service hours

Grease Type: Cat Advanced 3M™ (or equivalent)

Volume: 400-500cc per fitting

Tools Required:

1-1/4" impact socket (for mounting bolts)

50-ton jack + stand

Track press (for chain removal)

Flange Thickness:

New: 35 mm

Replace at: ≤18 mm

Bearing Play:

Allowable: ≤1.8 mm radial

Critical: >2.5 mm

Greasing:

Interval: Every 10 service hours

Grease Type: Cat Advanced 3M™ (or equivalent)

Volume: 400-500cc per fitting

Tools Required:

1-1/4" impact socket (for mounting bolts)

50-ton jack + stand

Track press (for chain removal)

Step-by-Step:

Release track tension (grease cylinder)

Remove master pin/chain (if needed)

Support idler with hoist

Unbolt (torque: 650-700 Nm for M24 bolts)

Inspect track frame bushings

Install new idler with anti-seize compound

Step-by-Step:

Release track tension (grease cylinder)

Remove master pin/chain (if needed)

Support idler with hoist

Unbolt (torque: 650-700 Nm for M24 bolts)

Inspect track frame bushings

Install new idler with anti-seize compound

OEM vs Aftermarket Comparison

Factor OEM (Cat) Premium Aftermarket Price 4,100 3,400 Lead Time 3-6 weeks 2-4 weeks Warranty 12 months 6-12 months Bearing Life 10,000-12,000 hrs 8,000-10,000 hrs Seal Effectiveness 97%+ 90-95%

| Factor | OEM (Cat) | Premium Aftermarket |

|---|---|---|

| Price | 4,100 | 3,400 |

| Lead Time | 3-6 weeks | 2-4 weeks |

| Warranty | 12 months | 6-12 months |

| Bearing Life | 10,000-12,000 hrs | 8,000-10,000 hrs |

| Seal Effectiveness | 97%+ | 90-95% |

Recommended Suppliers

OEM:CQC-track/DPW-PARTS

OEM:CQC-track/DPW-PARTS

Troubleshooting Guide

Symptom Root Cause Solution Track misalignment Worn flanges Replace idler Grease leakage Seal failure Rebuild with 6I-5995 kit Vibration Bearing spalling Immediate replacement Idler not rotating Rust seizure Disassemble/clean

| Symptom | Root Cause | Solution |

|---|---|---|

| Track misalignment | Worn flanges | Replace idler |

| Grease leakage | Seal failure | Rebuild with 6I-5995 kit |

| Vibration | Bearing spalling | Immediate replacement |

| Idler not rotating | Rust seizure | Disassemble/clean |

Pro Tips

For LGP Models:

Use wider idler-specific grease tools

Check clearance to ripper mounts

Mining Applications:

Upgrade to "HD" idlers with thicker flanges

Increase greasing frequency to 5-8 hours

Storage:

Rotate stored idlers quarterly to prevent bearing brinelling

Need Exact Part Verification?

Provide:

Serial number (located on right frame rail)

Current idler photos (show flange wear)

Application (e.g., swamp, mining, demolition)

I can then supply:

Exploded diagrams

Local dealer contacts

Cross-section wear measurements

For LGP Models:

Use wider idler-specific grease tools

Check clearance to ripper mounts

Mining Applications:

Upgrade to "HD" idlers with thicker flanges

Increase greasing frequency to 5-8 hours

Storage:

Rotate stored idlers quarterly to prevent bearing brinelling

Need Exact Part Verification?

Provide:

Serial number (located on right frame rail)

Current idler photos (show flange wear)

Application (e.g., swamp, mining, demolition)

I can then supply:

Exploded diagrams

Local dealer contacts

Cross-section wear measurements