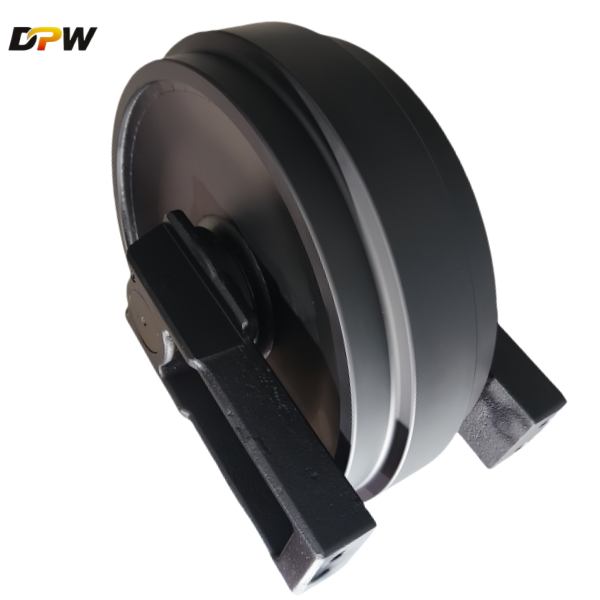

CAT325/329 forged front idler assembly-1028155-1153696/China forged idler manufacture in Quanzhou ,China.

Product Specifications

(102-8155 / 115-3696) CAT 325/329 Forged Front Idler Assembly is a heavy-duty undercarriage component designed for Caterpillar 325 and 329 excavators, ensuring smooth track movement and proper alignment. Here’s what you need to know:

Key Features & Specifications

✔ Compatibility: Fits CAT 325B, 325C, 325D, 329D (verify exact model match).

✔ Material: Forged steel construction for superior strength and wear resistance.

✔ Sealing: Advanced seal technology (typically multi-lip or labyrinth seals) to keep out debris and retain grease.

✔ Lubrication: Grease-lubricated for reduced friction and extended lifespan.

✔ Bearing Type: Tapered roller bearings for high load capacity.

Functions of the Front Idler

Maintains track tension and alignment.

Absorbs shock loads during operation.

Helps distribute machine weight evenly across the undercarriage.

Signs of a Worn-Out Idler

⚠ Excessive side-to-side movement (indicates bearing wear)

⚠ Visible cracks, dents, or uneven wear on the idler wheel

⚠ Grease leakage (seal failure)

⚠ Abnormal track noise or misalignment

Replacement Recommendations

Replace in pairs (left & right) to ensure balanced performance.

Inspect sprockets, rollers, and track chains simultaneously—wear in one part accelerates damage to others.

OEM vs. Aftermarket:

CAT OEM – Best fit, highest durability, but expensive.

Aftermarket (Berco, ITR, Vema Track) – Cost-effective, but verify quality.

Top Aftermarket Brands

1️⃣ DPW – Premium aftermarket, close to OEM quality.

2️⃣ CQC – Reliable mid-range option.

3️⃣ WHW – Budget-friendly but decent lifespan.

Installation Tips

🔧 Clean the mounting area before installation.

🔧 Check track tension after replacement (refer to CAT specs).

🔧 Torque bolts properly to prevent loosening under vibration.

Where to Buy?

CAT Dealers (for OEM parts)

Undercarriage specialists (e.g., TractorZone, Tracks N Teeth)

Online marketplaces (eBay, Amazon Industrial, Alibaba—verify seller reputation)

Need help finding the best deal or confirming compatibility? Let me know your exact machine model & serial number!