CAT-D11N/D11R-Bulldozer Front Idler Assembly-Heavy-duty dozer undercarriage component manufacture Supplier based in Quanzhou China

Product Specifications

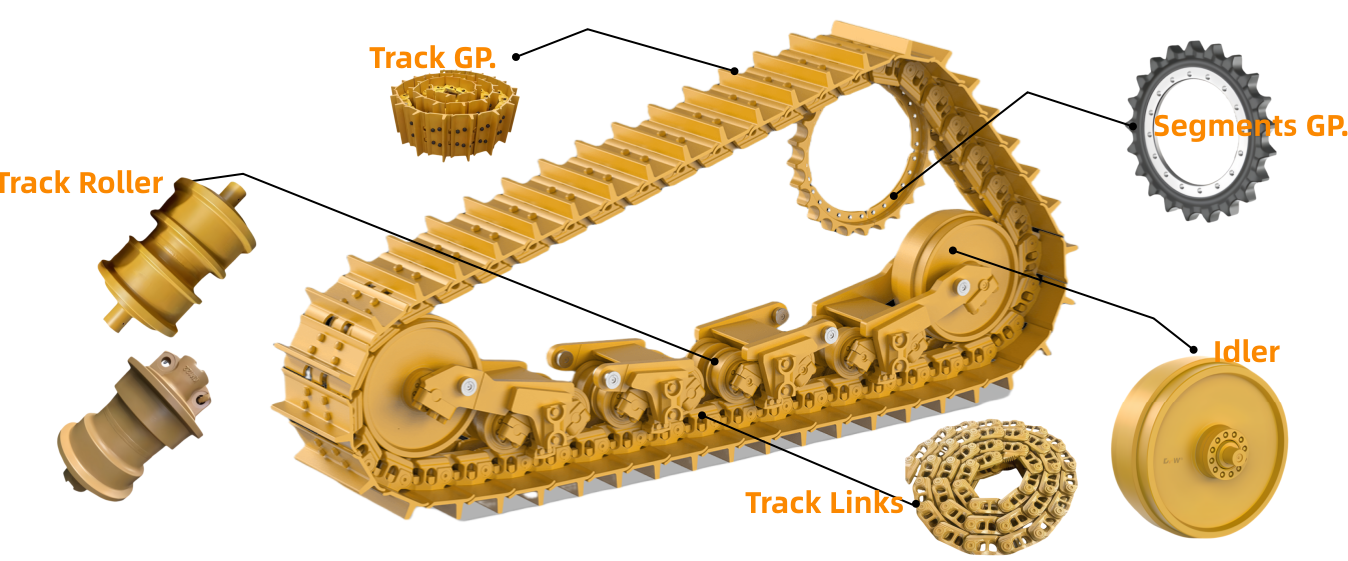

Bulldozer CAT D11N/D11R Front Idler Assembly – a critical component for the world's largest bulldozers:

1. Core Function & Machine Context

Role: Frontmost track component supporting 100+ ton loads while guiding tracks, maintaining tension, and absorbing ground impacts.

Machine Compatibility:

CAT D11N 4HK-1, D11N 74Z-1 , D11R-9TR CX-1, D11R 9XR-1 dozers

Serial Number Prefix Critical (e.g., D9D, MDB, WCB)

Operating Environments: Mining, quarrying, heavy earthmoving (extreme abrasion/shock loads).

2. Key Design Features

| Feature | Specification |

|---|---|

| Construction | Casted steel core (monolithic for max strength) |

| Weight | 3,200–4,500 kg (7,000–10,000 lbs) |

| Flange Height | 180–220 mm (protects track chain links) |

| Bearing System | Tapered roller bearings + triple-lip seals |

| Lubrication | Centralized greasing ports (SAE 0 EP grease) |

3. Technical Specifications

Dimensions:

Outer Diameter: 890–930 mm

Bore Diameter: 150–180 mm

Track Rail Width: 35" or 42" (config-specific)

Load Capacity:

Static: >50 metric tons

Dynamic Impact: 150+ metric tons (rock strike)

OEM Part Numbers:

D11N:148-3729/CR5676B

D11R EX:156-0313

Always verify via S/N

4. Failure Risks & Detection

Common Issues:

Bearing seizure (inadequate lubrication)

Flange wear >25% thickness

Seal leaks (contaminated grease)

Inspection Protocol:

Check every 250 hrs: Seal integrity, flange cracks, abnormal track slap

Measure flange wear monthly (replace if <65% OEM thickness)

5. Replacement Cost Analysis

| Option | Price Range | Lifespan |

|---|---|---|

| Genuine CAT | $28,000–$42,000 | 12,000–18,000 hrs |

| Certified Aftermarket | $18,000–$26,000 | 8,000–12,000 hrs |

| Remanufactured | $12,000–$18,000 | 6,000–9,000 hrs |

6. When to Replace (Critical Signs)

✅ Track derailment during turns

✅ Visible metal fragments in grease

✅ >5° idler wobble during operation

✅ Abnormal grinding noises at idle

7. Specific Sourcing Guide

OEM Dealers: Use CQC

Top Aftermarket Brands: DPW, CQC (demand ISO 9001 certs)

GEO Keywords: "CAT D11 idler near me," "mining dozer parts Australia," "D11 undercarriage supplier Chile"

8. Installation Best Practices

Torque Specs:

Mounting bolts: 1,900–2,200 N·m (1,400–1,600 lb-ft)

Track Tension:

1.5–2" sag (mid-roller to track rail)

Post-Install Checks:

10-hr infrared scan for bearing overheating

Pro Tip: For D11s in hard-rock mining, genuine CAT forged idlers deliver 40% longer life than premium aftermarket. In less severe conditions, certified remanufactured assemblies offer optimal TCO.

Final Note: Always reference your D11’s full serial number (6T8721/CR5676B) when ordering – a single digit error causes catastrophic incompatibility. Maintain forced-lubrication systems bi-weekly to prevent $100k+ undercarriage failure cascades.