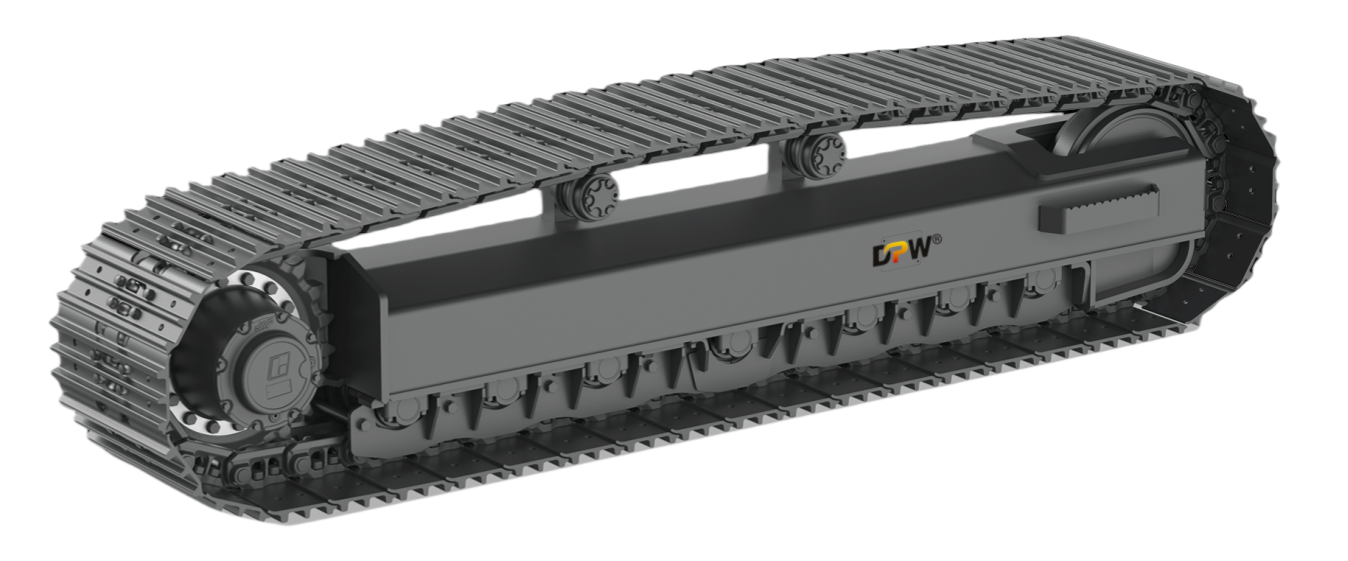

CASE CX460/CX470B/CX490DLC/SK480/SH400/E485 Track Lin Chain Assy SI1057/50/Earthmoving Construction and Mining Undercarriage Components manufacture

Product Specifications

Case CX460 Track Link Assembly refers to the complete set of interconnected components that form the tracked chain system for the Case CX460 excavator. This assembly is critical for transmitting power from the final drive to the track, enabling machine movement under heavy-load conditions. Below is a detailed technical overview based on industry standards and typical specifications for such components:

1. Composition & Components

A track link assembly typically includes:

Track Links: Forged or cast steel components that form the chain structure.

Track Pins: Hardened steel pins connecting adjacent links, subject to high shear stress.

Track Bushings: Sleeves that reduce wear between pins and links (also called or "track bush").

Track Shoes: Attached to links for ground traction .

Bolts & Nuts: High-tensile fasteners ( Grade 12.9) for securing shoes to links.

2. Key Specifications

Material: High-carbon or alloy steel (e.g., 40Mn2, 50Mn) for links and pins, heat-treated to 45-55 HRC for wear resistance.

Compatibility: Designed specifically for Case CX460 excavators (approx. 45-50 ton class).

Load Capacity: Rated for dynamic loads exceeding 10,000 kg per roller station.

Sealing: Integrated dust seals to retain lubrication and prevent contamination.

3. Manufacturing Process

Forging/Casting: Links are forged for strength or cast for complex shapes.

Machining: Precision drilling for pin/bushing alignment.

Heat Treatment: Quenching and tempering to achieve core toughness and surface hardness.

Quality Checks: Dimensional verification, magnetic particle inspection for cracks.

4. Performance Features

Durability: Resists abrasion in rocky, sandy, or muddy environments.

Interchangeability: OEM-equivalent dimensions ensure direct replacement.

Maintenance: Sealed lubrication extends service intervals (e.g., 500-1,000 hours).

5. Applications

Earthmoving: Excavation, trenching, and loading.

Mining: Heavy-duty material handling.

Construction: Site development and infrastructure projects.

6. Industry Standards

Quality Certifications: ISO 9001, CE marking.

Testing: Meets ASTM A148 for steel castings and DIN standards for pin hardness.

7. Maintenance Signs for Replacement

Elongation: Chain stretch beyond 3% indicates wear.

Pin/Bushing Wear: Visible scoring or reduced diameter.

Track Misalignment: Uneven wear on shoes or rollers.

8. Supplier Information

Manufacturers like Heli Heavy Machinery (as noted in your previous query) often produce such assemblies, offering:

OEM-compatible parts.

Material certifications (e.g., Mill Test Reports).

Customization for specific operating conditions.

Key Terminology

Track Link Assembly

Track Pin

Track Bushing

Track Shoe

Drive Sprocket