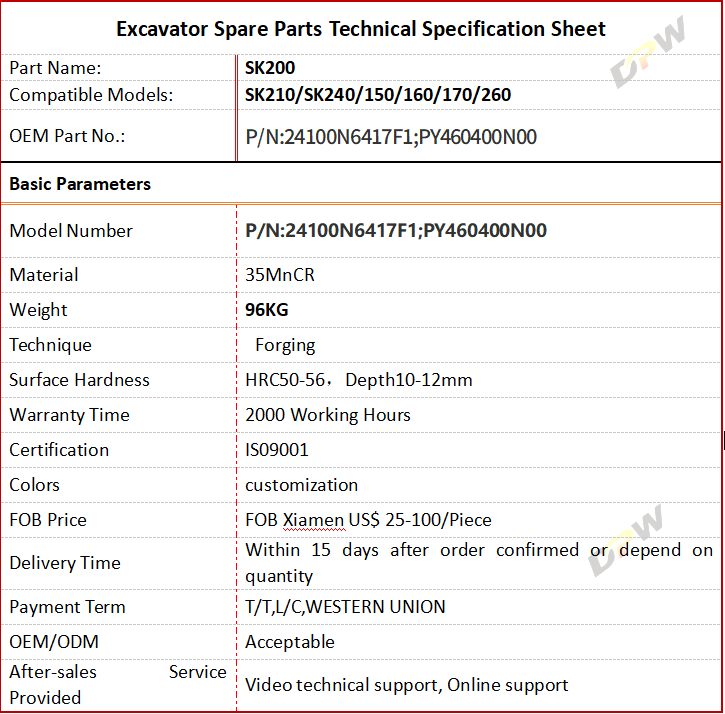

(P/N:24100N6417F1;PY460400N00)KOBELCO -SK210 front idler assembly/china idlers factory/china excavator idler/track idler roller factories

Product Specifications

(P/N:24100N6417F1;PY460400N00)KOBELCO -SK210 front idler assembly/china idlers factory/china excavator idler/track idler roller factories

Key Features & Benefits

✔ Full Forged Assembly – Includes front idler, bottom rollers, and carrier rollers for complete undercarriage reinforcement

✔ Alloy Steel Construction – High-density forged material for 50% longer lifespan vs. cast idlers

✔ Deep Hardened Surface (HRC 55-60) – 4-6mm induction-hardened depth for maximum wear resistance

✔ Double-Sealed Bearings – Protects against dirt, water, and debris in harsh environments

✔ OEM-Exact Fit – Direct replacement for Komatsu SK210LC, Hitachi ZX210, Caterpillar 320, and Volvo EC210

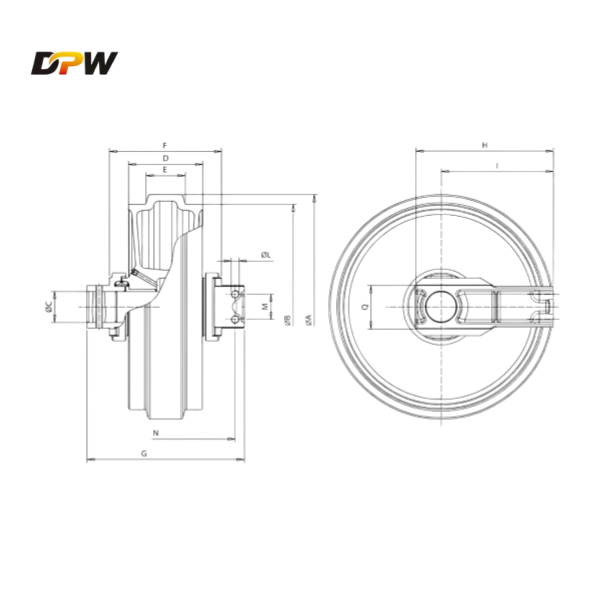

Technical Specifications

| Parameter | Specification |

|---|---|

| Dynamic Load Capacity | 10,500 kg |

| Bearing Type | Heavy-duty tapered roller bearings |

| Flange Thickness | 20mm (reinforced) |

| Weight (Full Assembly) | 96 kg (approx.) |

| Hardness Depth | 4-6mm induction-hardened |

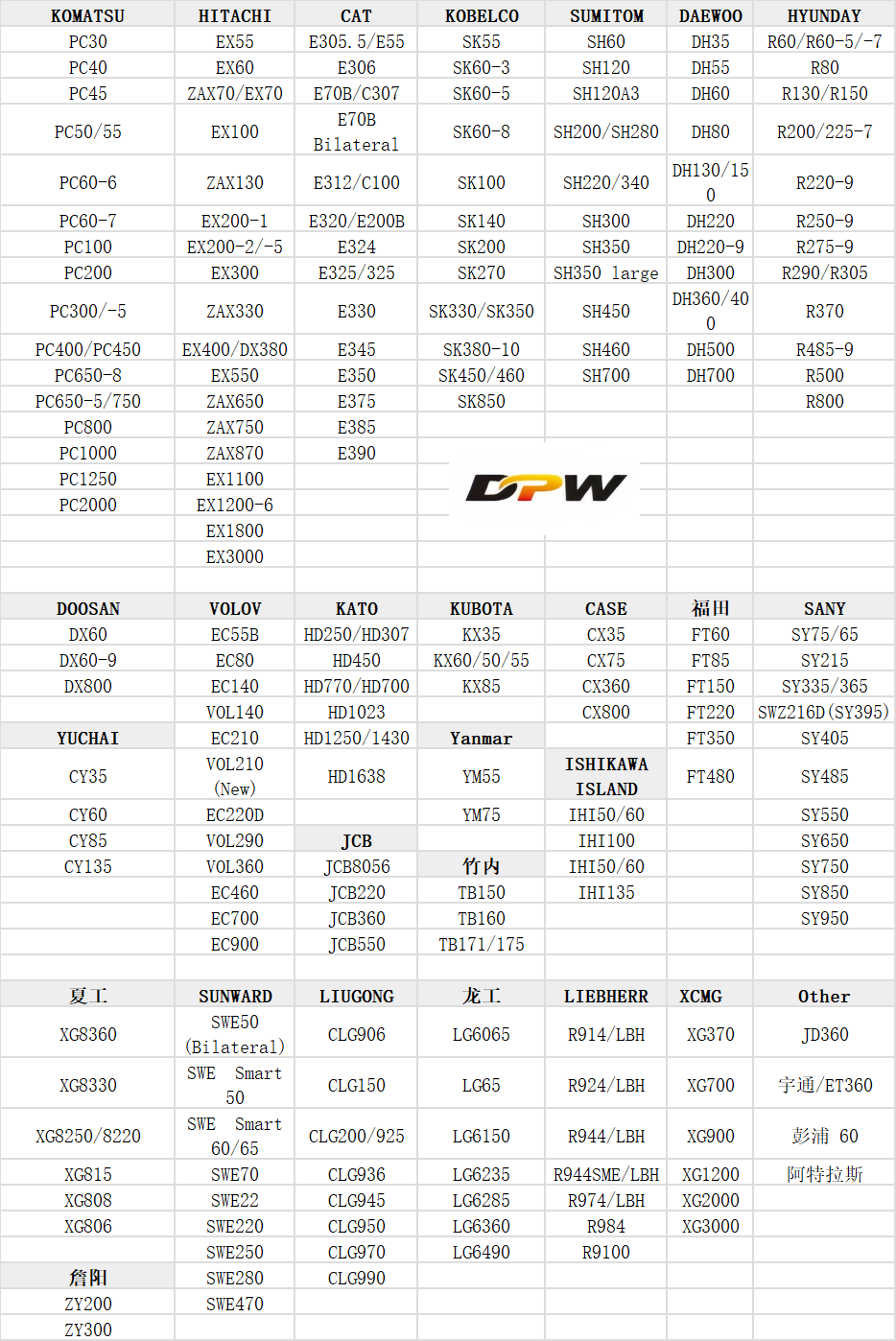

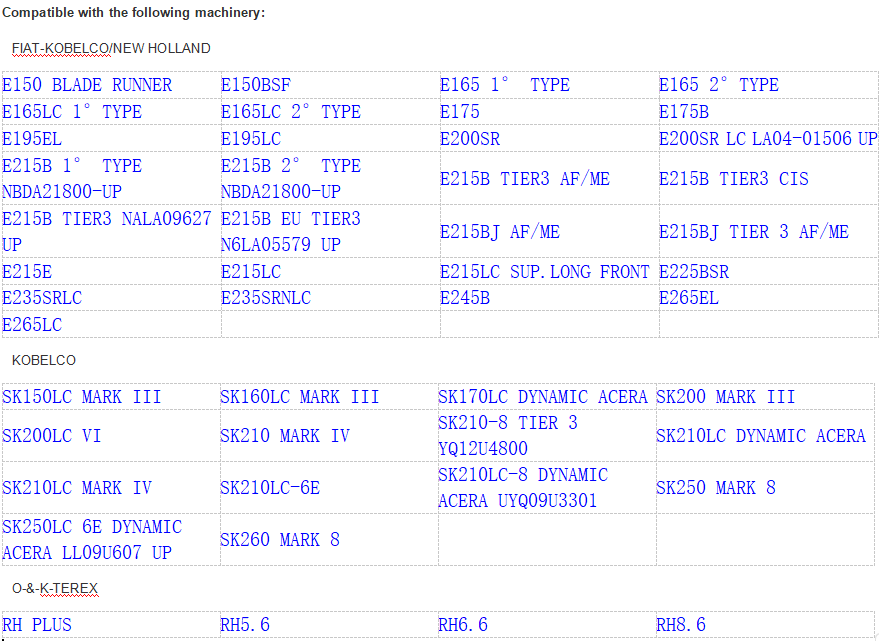

Compatible Machines

Why Choose Forged Idlers Assembly?

✅ Full Undercarriage Protection – Matched set ensures balanced performance

✅ Higher Load Capacity – Supports heavy digging and lifting operations

✅ Reduced Downtime – Fewer replacements and lower maintenance costs

✅ Mining & Quarry-Ready – Handles abrasive materials like granite, iron ore, and limestone

When to Replace SK210LC Idlers Assembly?

⚠ Excessive track sagging or misalignment

⚠ Visible cracks, spalling, or deep wear grooves

⚠ Bearing noise or rough rotation

⚠ Grease leakage from damaged seals

Maintenance Recommendations

Clean weekly – Remove packed mud and abrasive debris

Inspect every 500 hours – Check flange wear and bearing play

Replace as a full set – Ensures uniform track tension and alignment

Available Upgrades

Tungsten Carbide Coating (TCC) – For extreme-wear mining applications

Telemetry-Enabled Rollers – RFID wear sensors for predictive maintenance

Arctic/Cold Weather Package – Special seals for sub-zero conditions

Ordering Information

Standard Assembly: SK210LC-FORGED (Black oxide finish)

Heavy-Duty (HD): SK210LC-HD (Tungsten carbide-coated rollers)

Mining-Grade (XD): SK210LC-XD (Extra-thick flanges + hardened core)

Need a custom solution? Provide:

Machine model & serial number

Current undercarriage condition

Primary work environment (e.g., rock, demolition, mining)

Also available with matching forged sprockets & HD track chains for a complete undercarriage overhaul.