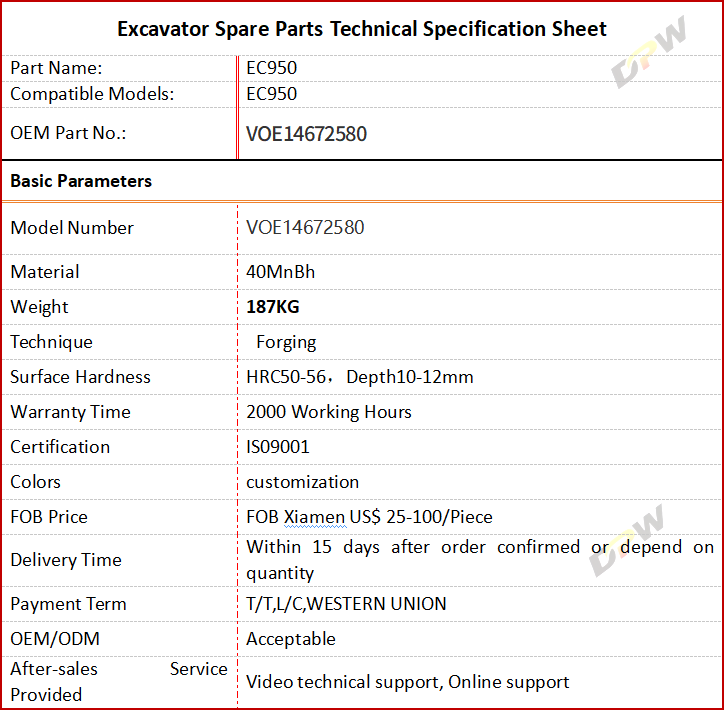

VOLVO excavator EC950( VOE14672580)final drive sprocket/sprocket wheel/sprocket rim factory

Product Specifications

VOLVO excavator EC950( VOE14672580)final drive sprocket factory-China spare parts factories

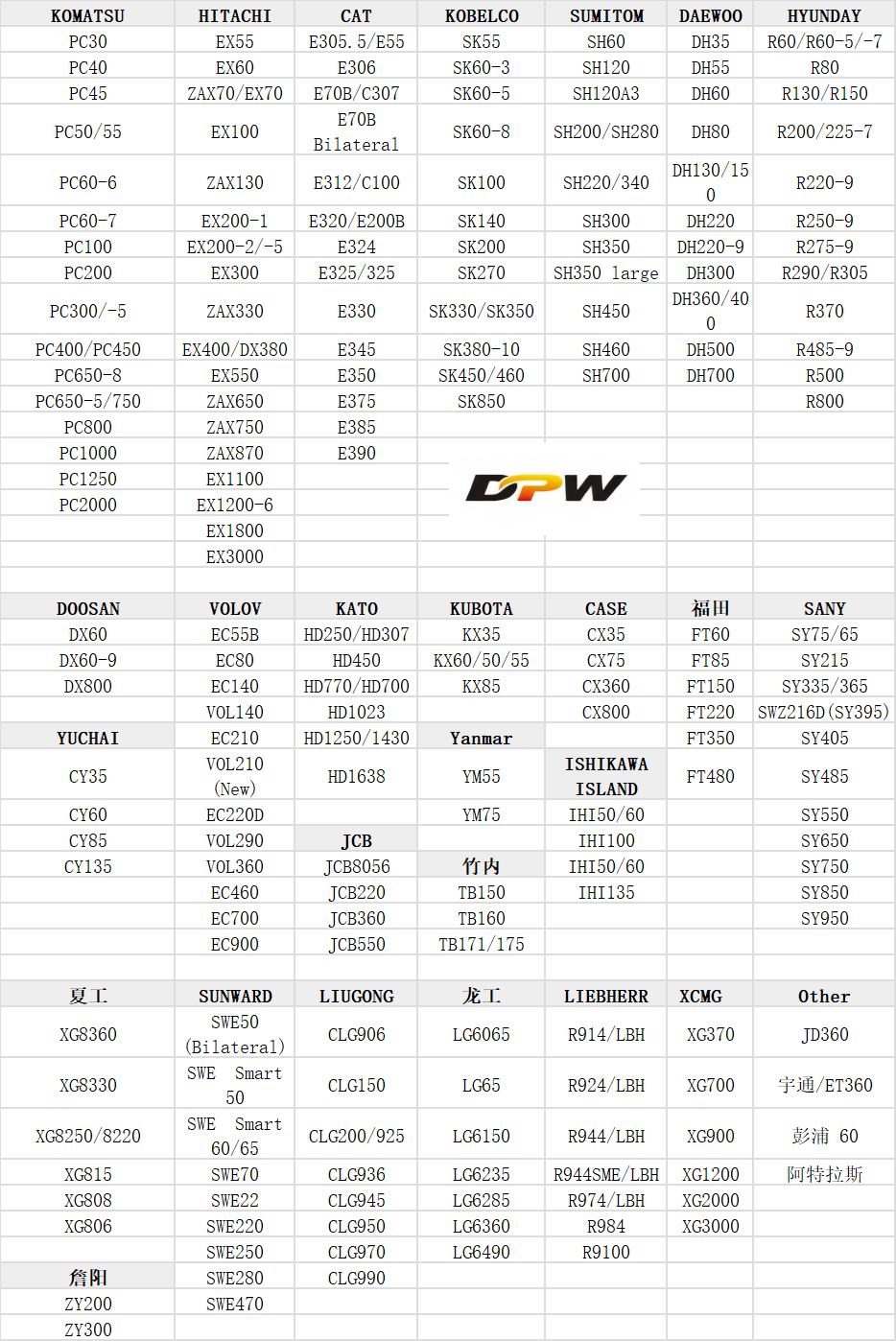

CQC focus on manufacturer volvo mining heavy duty machinery volvo undercarriage spare parts below:

- Volvo EC950 Track shoes assembly 51Links EC950 track group VOE14761630 Track assy

- Volvo EC950 Track link assembly Voe14761640 Volvo 950 track chain 51Linsk RC950 track links assy EC950 track chain assembly Voe14672610

- Volvo EC950 Double grouser Track shoes 650mm EC950 steel track plates EC950 double bar track pads VOE14672620

- Volvo EC950 track bolts of shoes VOE14672630

- Volvo EC950 track Nuts of shoes VOE14672631

- Volvo EC950 Carrier rollers Volvo 950 Top rollers EC950 upper rollers NEW VOE14672540

- Volvo EC950 Sprocket VOE14672580 EC950 drive sprocket EC950 sprocket wheel Made in China

- Volvo EC950 Sprocket Bolts VOE993011 Hex Screw

- Volvo EC950 Sprocket Washer VOE992051

- Volvo EC950 front idlers EC950 idlers wheel VOE14743661

Key Features of EC950 Sprockets

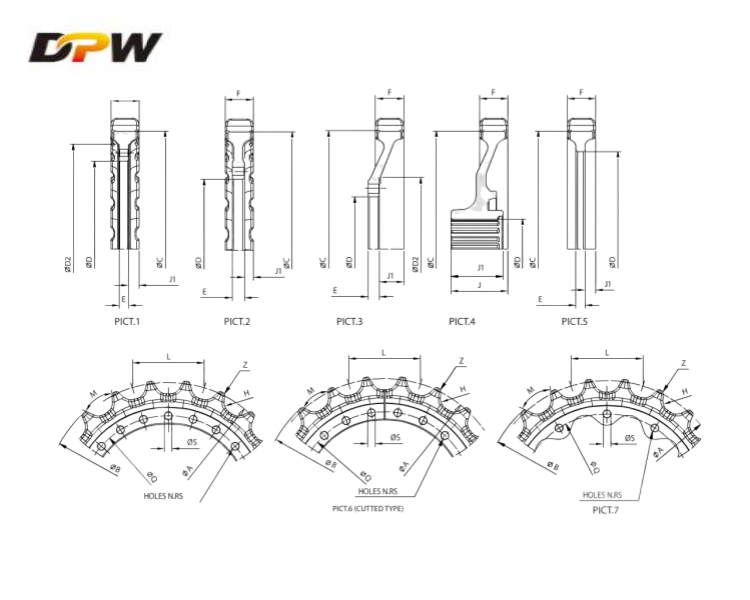

✔ High-Strength Alloy Steel – Forged or heat-treated for superior wear resistance and impact strength.

✔ Optimized Tooth Design – Ensures smooth engagement with track chains, reducing wear and noise.

✔ Extended Service Life – Hardened teeth and reinforced structure for longer operation in harsh conditions.

✔ Compatibility – Designed to fit major OEM undercarriage systems (Caterpillar, Komatsu, Hitachi, etc.).

Applications

Mining excavators (e.g., Cat 349, Komatsu PC2000)

Large bulldozers (e.g., Cat D11, Liebherr PR 776)

Heavy-duty track loaders & material handlers

Signs of Worn Sprockets

- Uneven tooth wear or "hooking"

Excessive track chain slippage

Cracks or broken teeth

Abnormal grinding noise during operation

Why Choose EC950 Sprockets?

Reduces downtime – Longer lifespan than standard sprockets.

Cost-effective – Minimizes track chain wear, lowering total maintenance costs.

Precision-machined – Ensures perfect alignment with track links.

Maintenance Tips

✔ Inspect regularly – Check for wear patterns and cracks.

✔ Replace in sets – Sprocket + track chain + rollers for optimal performance.

✔ Keep undercarriage clean – Prevent abrasive damage from dirt and rocks.

Need a quote or compatibility check for your machine? Let me know your equipment model!