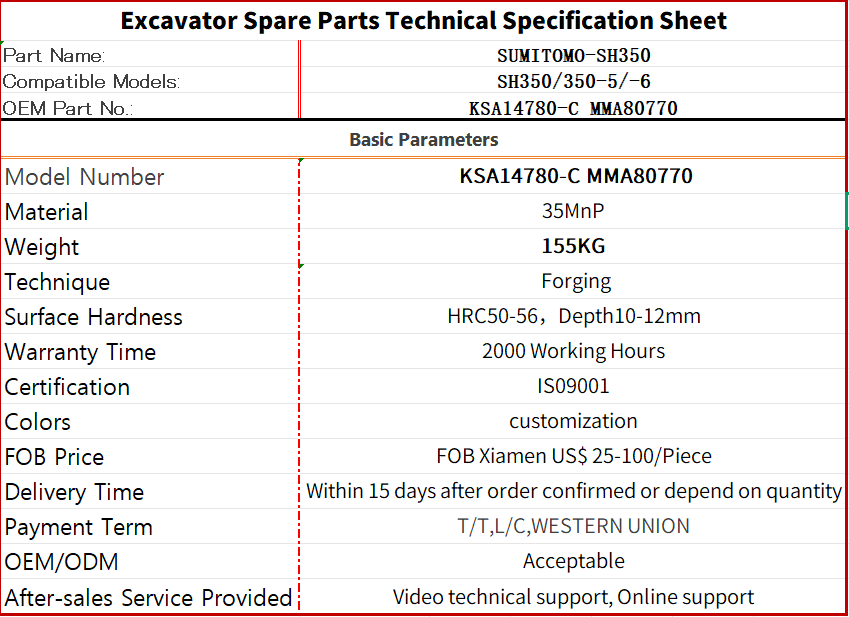

SUMITOMO-SH350 FRONT IDLER( KSA14780-C;KSA11770)front idler wheel ass'y/forge idler manufacture/excavator crawler undercdarriage parts factory

Product Specifications

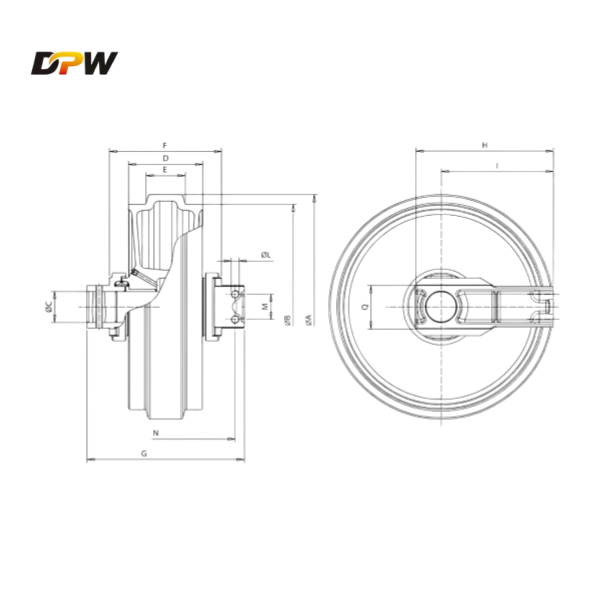

SH350-5/6 Forged Idlers – Heavy-Duty Track Rollers for 35-Ton Excavators

SH350-5/6 forging idlers are ultra-durable undercarriage components designed for 35-45 ton excavators, built to withstand extreme conditions in mining, quarrying, and heavy construction. Manufactured through precision hot forging, these idlers offer superior strength and longevity compared to standard cast rollers.

SUMITOMO-SH350 FRONT IDLER( KSA14780-C;KSA11770)front idler wheel ass'y/forge idler manufacture/excavator crawler undercdarriage parts factory

Key Features & Benefits

✔ Forged Alloy Steel Construction – Higher density, fewer defects, and better fatigue resistance than cast idlers

✔ Deep Induction Hardening (HRC 55-60) – 4-6mm hardened depth for maximum wear resistance

✔ Double-Labyrinth Sealed Bearings – Prevents contamination in wet, muddy, or dusty environments

✔ Optimized Flange Design – Reinforced double flanges for better track guidance and reduced derailment risk

✔ OEM Interchangeable – Direct replacement for Hitachi ZX350, Komatsu PC350, Caterpillar 336, and Volvo EC350 models

Technical Specifications

| Parameter | Specification |

|---|---|

| Load Capacity | 14,000 kg (dynamic) |

| Bearing Type | Heavy-duty tapered roller bearings |

| Flange Thickness | 25mm (reinforced) |

| Weight | 95 kg (standard) |

| Surface Treatment | Shot-peened for stress relief |

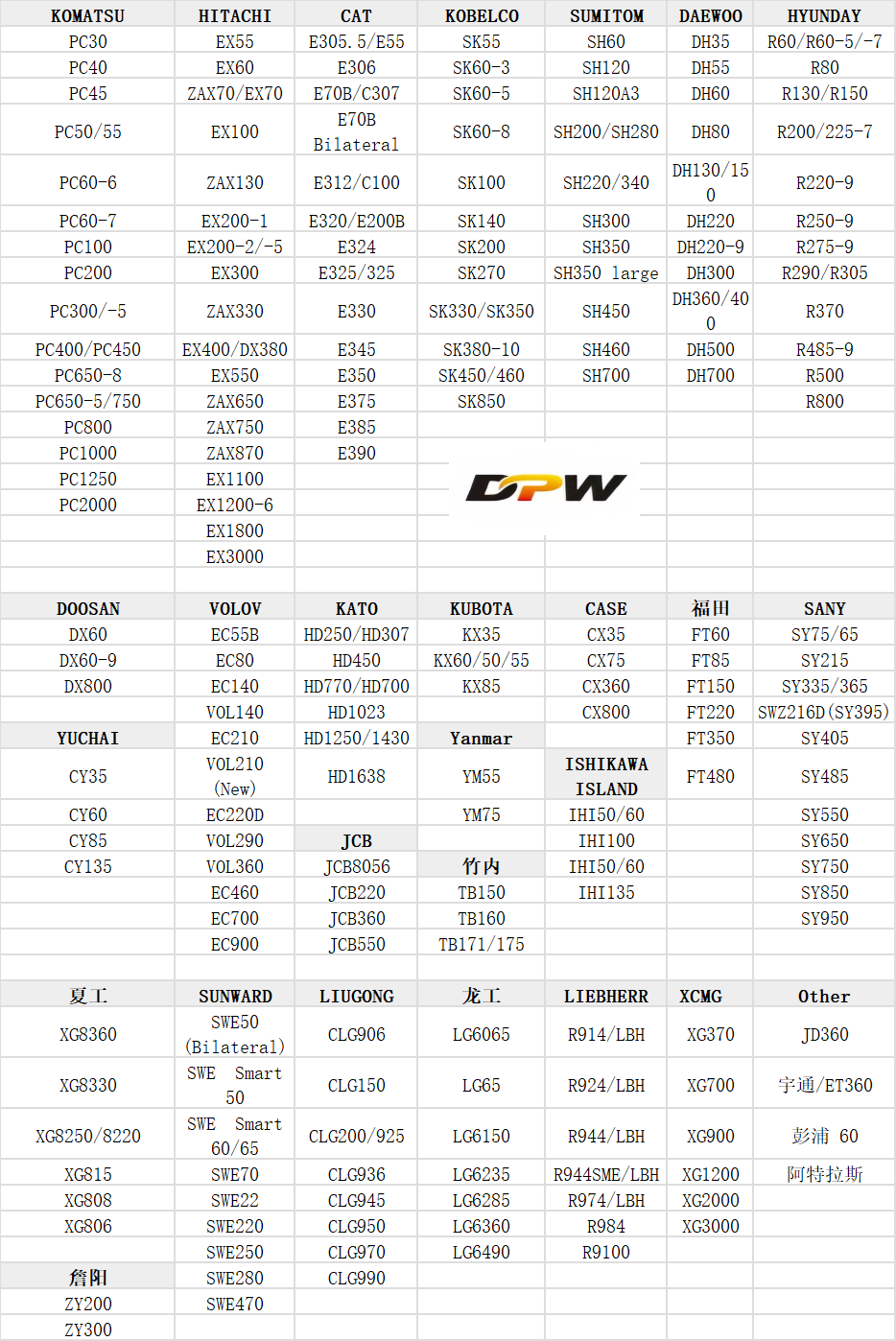

Compatible Machines

Hitachi ZX350-5/ZX350-6

Komatsu PC350-8/PC350LC-11

Caterpillar 336D2/336F L

Volvo EC350/EC380

Hyundai HX350/HX380

Why Choose Forged Idlers?

✅ 40% Longer Service Life – More resistant to wear, cracks, and deformation

✅ Higher Impact Resistance – Withstands shock loads from rock and demolition work

✅ Reduced Maintenance Costs – Fewer replacements and less downtime

When to Replace SH350-5/6 Idlers?

⚠ Flange wear exceeds 30% of original thickness

⚠ Visible cracks, spalling, or deep grooves on the rolling surface

⚠ Bearing play >2mm or grinding noise during operation

⚠ Grease leakage due to seal failure

Maintenance Recommendations

Clean after each shift – Remove mud, rocks, and debris to prevent accelerated wear

Inspect every 500 hours – Check for abnormal wear patterns and bearing play

Replace in sets (minimum 2 idlers) – Ensures balanced track tension and alignment

Available Upgrades

Tungsten Carbide Overlay (TCO) – For extreme abrasion resistance in mining

Telemetry-Enabled Idlers – RFID sensors for real-time wear monitoring

Arctic/Cold Weather Version – Special seals and lubricants for sub-zero operations

Ordering Information

Standard: SH350-FORGED (Black Oxide Finish)

Heavy-Duty: SH350-HD (Tungsten Carbide Coated)

Mining-Grade: SH350-XD (Extra Thick Flanges + Hardened Core)

Need a custom solution? Provide:

Machine model & serial number

Current idler condition (photos/measurements if available)

Primary work environment (e.g., iron ore, granite, demolition)

Also available in complete undercarriage kits (sprockets + track chains + rollers) for full system optimization.

For mining or severe-duty applications, ask about our SH350-XD Forged Idlers with reinforced flanges and extended warranty options.

DPW-PARTS:thounsands of parts for you to choose from,custmize various chassis parts according to customer needs