Komatsu-PC1250 final drive sprocket(P/N:KM2420,21N2731191,722-51-11120)heavy excavator crawler under carriage parts/china sprockets factory

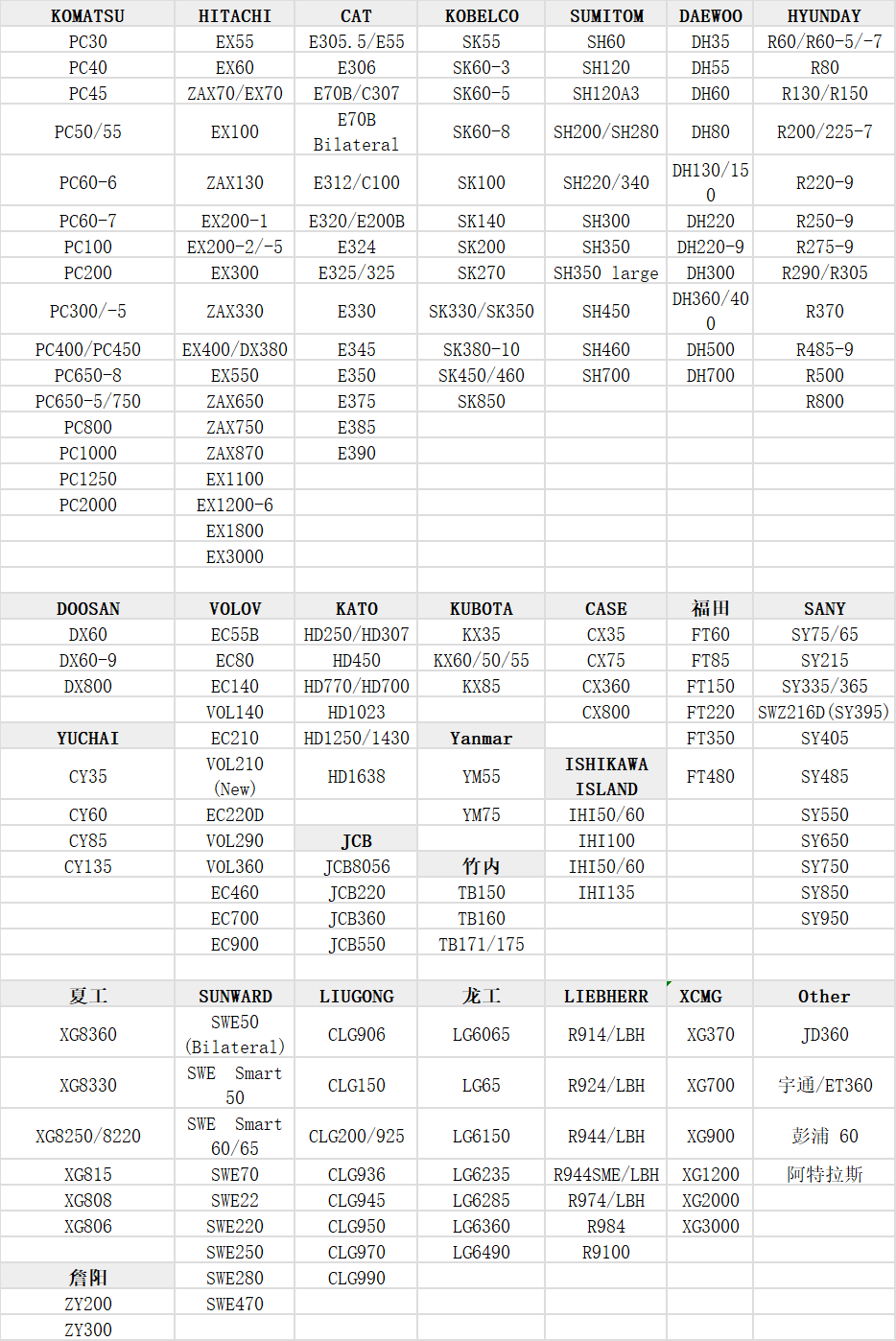

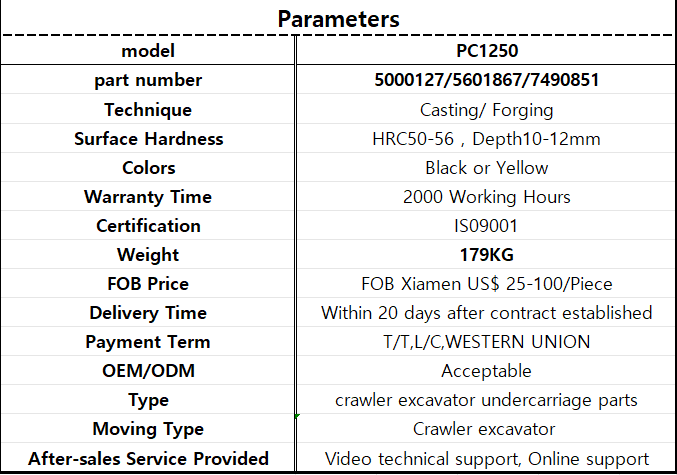

Product Specifications

Komatsu-PC1250 final drive sprocket(P/N:KM2420,21N2731191,722-51-11120)heavy excavator crawler under carriage parts

Here's a comprehensive guide to KOMATSU PC1250 sprockets, covering OEM and aftermarket options, maintenance tips, and replacement guidance:

Komatsu PC1250 Sprocket Specifications

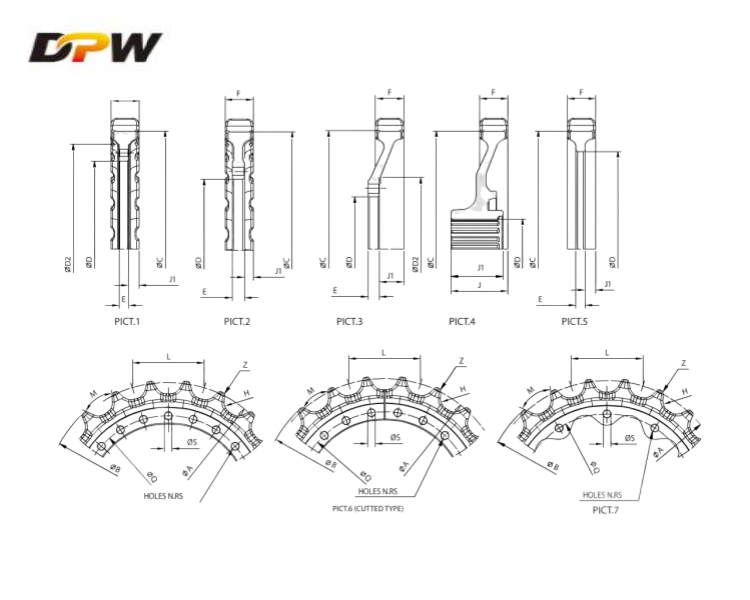

Type: Final drive sprocket (segment-type or one-piece)

Teeth Count: Typically 21-23 teeth (varies by model year)

Material: Forged alloy steel with induction-hardened teeth

Mounting: Bolted to final drive hub

Weight: ~150-200 kg (depends on design)

OEM Part Numbers

(Always verify with your machine serial number)

Complete Sprocket Assembly:

722-51-11110(older PC1250-6/7)722-51-11120(updated design)

Sprocket Segments:

722-51-11130(per segment)

Hardware Kit:

Bolts:

07316-00412(M24x2.5 flanged)Nuts:

07347-50412(prevailing torque)

Aftermarket Options

Premium Alternatives:

Berco (Italy) - Matches OEM quality

ITR (USA) - Durable mining-grade

VSE (Korea) - Cost-effective

Cost Comparison:

OEM: 7,000

Aftermarket: 5,000

When to Replace

Wear Indicators:

Teeth become hook-shaped (>30% wear)

Bolt holes elongated

Cracks in root areas

Service Life:

8,000-12,000 hours (depends on conditions)

Replacement Guide

Preparation:

Block machine on level surface

Release track tension

Removal:

Remove track chain

Unbolt sprocket (impact wrench recommended)

Use lifting sling (1-2 ton hoist)

Installation:

Clean hub mating surface

Torque bolts to 750-800 Nm (550-590 lb-ft)

Use thread locker (Komatsu #1200B)

Maintenance Tips

Monthly Inspection:

Check for loose bolts

Measure tooth thickness

Lubrication:

Final drive oil (ISO 68 grade)

Grease bolts during reassembly

Where to Buy

OEM Sources:

Komatsu dealers (www.komatsu.com)

Official parts portal

Aftermarket:

Undercarriage specialists

Mining equipment suppliers

Troubleshooting

| Issue | Solution |

|---|---|

| Premature wear | Check track chain pitch |

| Bolt failures | Verify torque specs |

| Noise/vibration | Inspect final drive alignment |

Need help with:

Finding your exact sprocket type?

Locating a local supplier?

Installation torque specs?

Let me know your machine serial number for precise information!