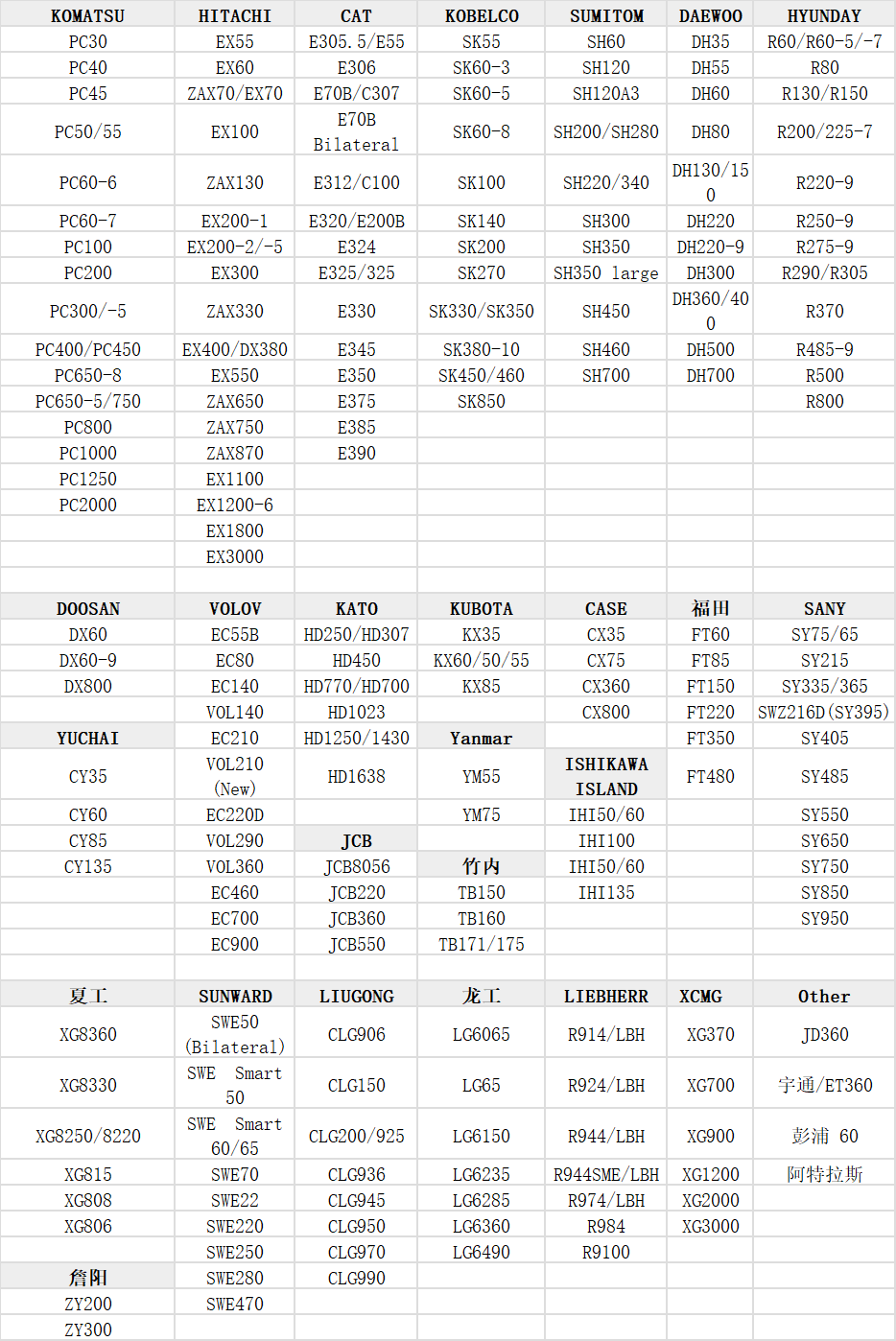

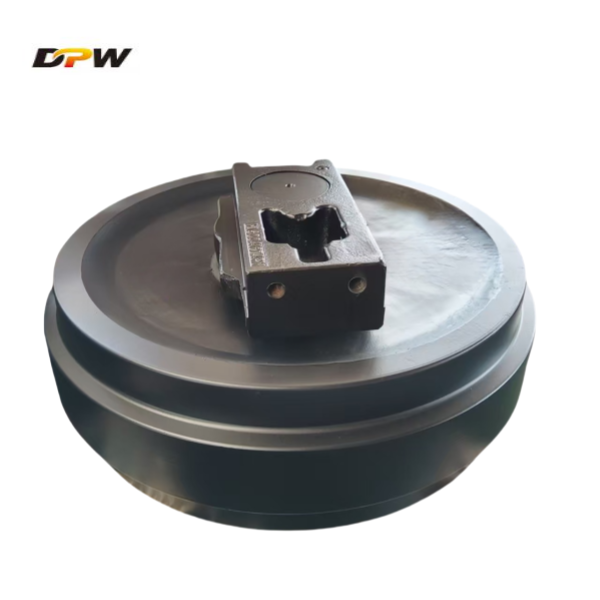

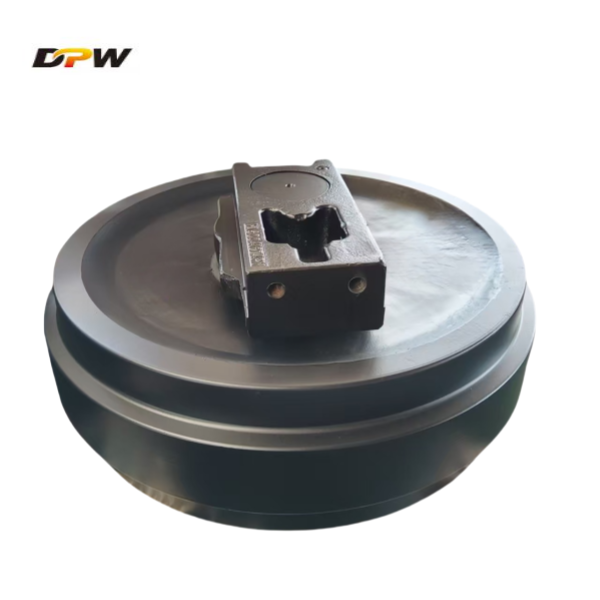

Hitachi crawler excavator parts ZAX350-5G(9306002)front idler assembly/China front wheel factory

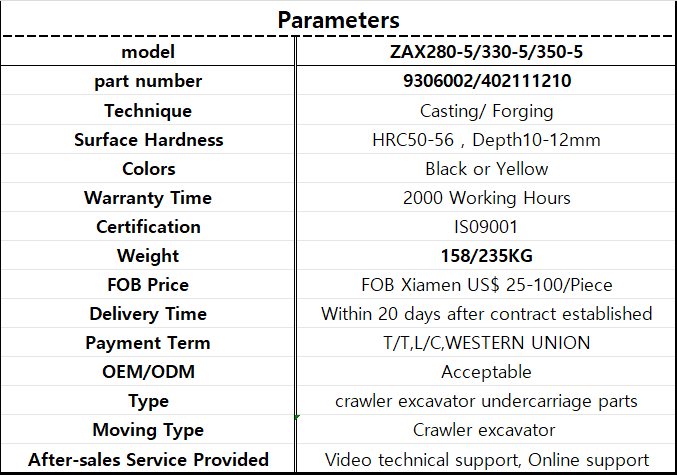

Product Specifications

(P/N&SKU:9306002)Hitachi ZAXIS 350-5 idler assembly, fit for zax280-5/330-5 machine,Hitachi aftermarket parts OEM manufacture

Here's a detailed breakdown of the Hitachi ZAXIS 350-5 idler assembly, covering OEM and aftermarket options, maintenance tips, and replacement guidance:

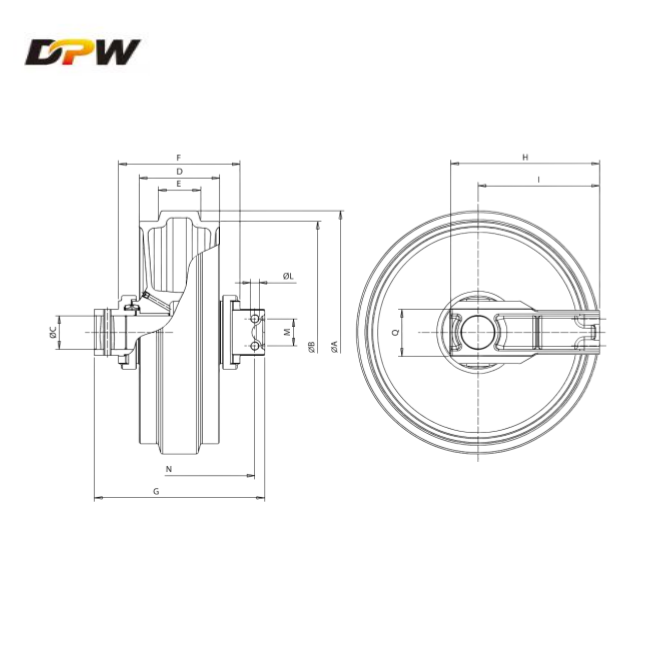

Hitachi ZAX350-5 Idler Specifications

Type: Adjustable front idler (grease tensioning)

Material: Forged steel with hardened wearing surfaces

Bearing Type: Double-row tapered roller bearings (sealed)

Weight: Forged120-150 kg ;casting230-240KG

Track Width Compatibility: 600mm or 700mm shoes (verify machine spec)

OEM Part Numbers

(Always confirm with your serial number at Hitachi Parts)

Complete Idler Assembly

404-21-11210(Standard idler for ZAX350-5)404-21-11220(Heavy-duty version)

Components

Idler wheel:

404-21-11231Bearing kit:

404-21-11240(includes seals)Tension cylinder:

404-21-11250

Aftermarket Options

Premium Alternatives:

Berco (Italy) - Direct OEM replacement

ITR (USA) - Mining-grade durability

Komatsu Undercarriage - Compatible designs

Cost Comparison:

OEM: 3,500

Aftermarket: 2,500

When to Replace

Wear Indicators:

Flange thickness <15mm (original ~25mm)

Visible cracks or pitting

Excessive play (>3mm radial movement)

Grease leakage from seals

Typical Service Life: 8,000-10,000 hours

Replacement Procedure

Preparation:

Park on level surface, block tracks

Release grease pressure from tension cylinder

Removal:

Remove track chain

Support idler with hoist

Unbolt mounting brackets (M24 bolts)

Installation:

Clean mating surfaces

Torque bolts to 450 Nm (332 lb-ft)

Lubricate with Hitachi GL-2 grease

Maintenance Tips

Monthly:

Check flange wear with calipers

Inspect for grease leaks

Verify track tension (25-35mm sag)

Annually:

Repack bearings (if serviceable type)

Replace tension cylinder seals

Where to Buy

OEM Sources:

CQCtrack

Aftermarket:

CQC&DPW-TRACK PARTS

Troubleshooting Guide

| Symptom | Likely Cause | Solution |

|---|---|---|

| Track misalignment | Worn idler flanges | Replace idler |

| Tension loss | Failed seals | Rebuild tension cylinder |

| Grinding noise | Bearing failure | Replace bearing kit |

Special Notes

The ZAX350-5 shares some undercarriage components with Komatsu PC350-8 (cross-reference possible)

Always replace idler seals when servicing

Consider replacing both idlers if one shows >50% wear

Need help with:

Specific torque specs?

Finding local suppliers?

Exploded diagrams?

Provide your machine serial number (located on right frame near cab) for precise information!