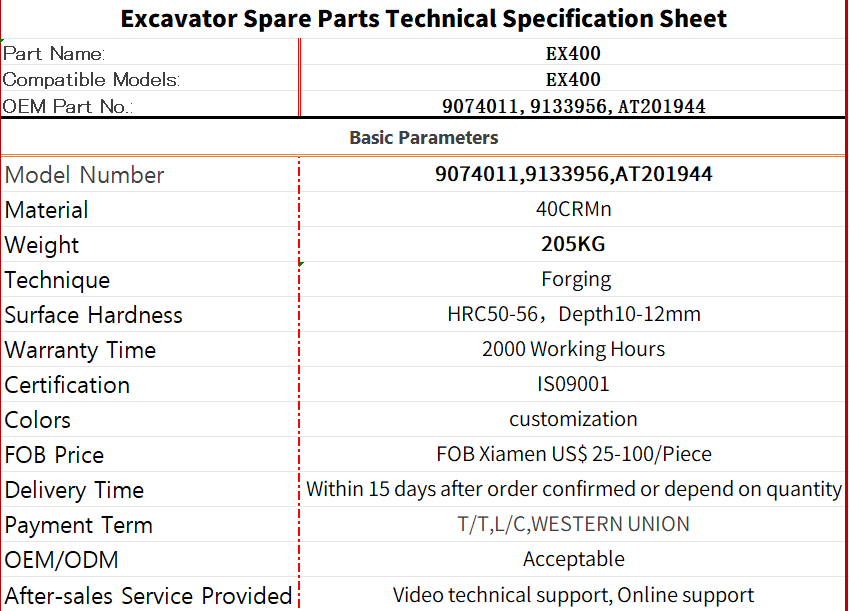

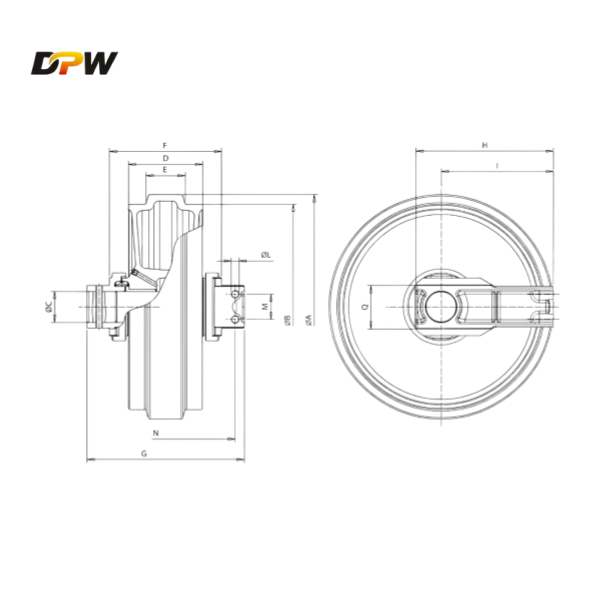

Hitachi EX400(9074011,9133956,AT201944) front idler forged/high quality idler fctory/idler ass'y/track idler undercarriage part

Product Specifications

Hitachi EX400(9074011,9133956,AT201944) front idler forged/high quality idler fctory/idler ass'y/track idler undercarriage part-Japan quality made in china

Key Advantages of Forged Construction

✔ 30% Higher Impact Resistance vs. cast idlers

✔ Superior Metal Density – Fewer voids/inclusions for structural integrity

✔ Extended Wear Life – Up to 2X longer service in abrasive environments

✔ Reduced Crack Risk – Ideal for high-shock load applications

Product Specifications

Material: High-carbon alloy steel, heat-treated to HRC 50-55 hardness

Bearing Type: Double-sealed, pre-lubricated roller bearings

Flange Design: Reinforced double flange for track guidance

Surface Treatment: Induction-hardened rolling surface (3-5mm depth)

Performance Comparison: Forged vs Cast Idlers

Feature EX400 Forged Idler Standard Cast Idler Service Life 8,000-10,000 hrs 3,000-5,000 hrs Failure Mode Gradual wear Sudden cracking Load Capacity 25% higher Standard Best For Mining, rock General earthmoving When to Upgrade to Forged Idlers?

▸ Operating in rocky/abrasive environments

▸ Experiencing frequent cast idler failures

▸ Running high-hour machines (>15,000 hrs)

▸ Needing to reduce unplanned downtimeMaintenance Guide

Every 250 hrs: Clean debris from flanges

Every 1,000 hrs: Check bearing play (<1.5mm)

Replace When:

Flange wear exceeds 35% thickness

Visible spalling on rolling surface

Bearing rotation becomes rough

Pro Tip: Pair with EX400 forged idlers and hardened track chains for complete undercarriage protection.

Need a custom solution? Provide:

Your exact machine model/year

Current idler part number (if available)

Primary material being handled (e.g., granite, iron ore)

Available with optional laser-etched wear indicators for easy monitoring!