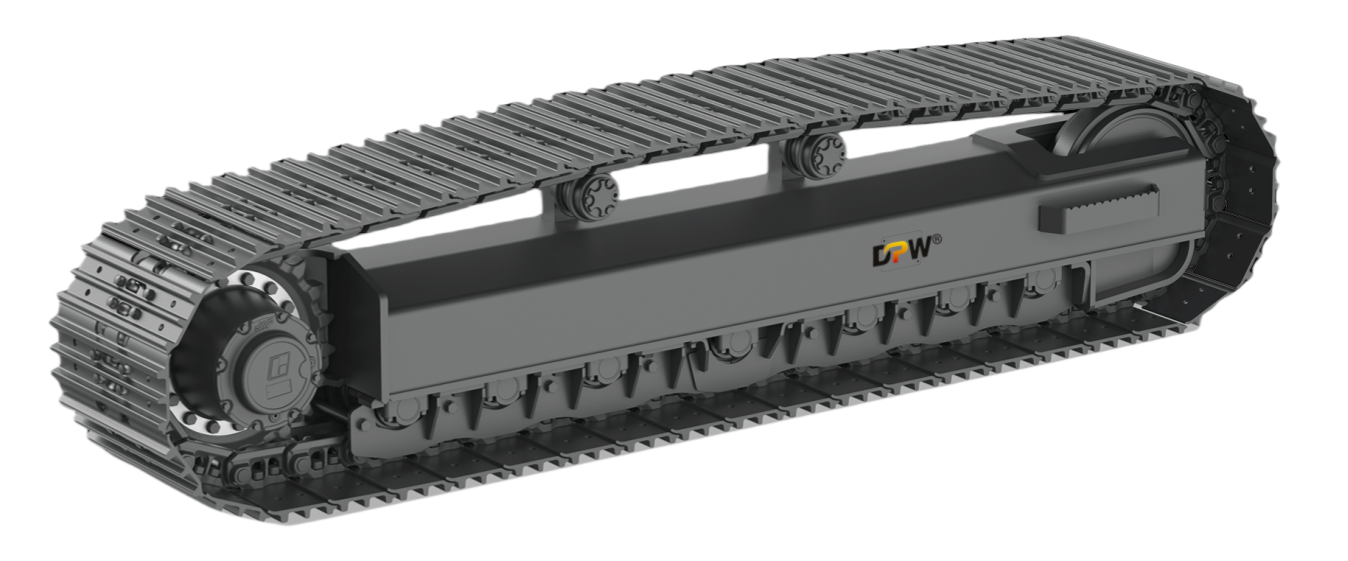

CAT E345GC/E330 Fabricated Idler Assy/Heavy duty crawler undercarriages source manufacture and supplier

Product Specifications

Key Components and Manufacturing:

Key Components and Manufacturing:- Rims: Fabricated idler rims can be made from hot-rolled steel or cast from a single piece.

- Hubs: Forged and heat-treated hubs are common, providing strength and durability.

- Side Plates: High-resistance welded side plates are used to connect the rim and hub.

- Bearings: Precision-pressed bearing housings and quality double-sealed bearings are essential for smooth rotation and longevity.

- Seals: Labyrinth seals help protect bearings from contaminants.

- Welding: Welding is a critical process in the fabrication of idlers, ensuring structural integrity.

- Finishes: Idler frames are often finished with paint, galvanization, or custom finishes to meet specific project requirements.

- Design and Applications:

- Idlers are fundamental components of crawler undercarriage systems, supporting the belt and guiding the flow of materials.

Excavators: - In excavators, idlers are part of the undercarriage, distributing weight and maintaining track alignment.

Material Handling: - Idlers are used in various industries for handling bulk materials, unit loads, and piece goods.

CEMA Standards: - Many idlers are designed and manufactured to meet or exceed CEMA (Conveyor Equipment Manufacturers Association) standards for load, life, and dimensions.

Customization: - Designs can be customized to suit specific applications, including troughing, return, impact, and self-aligning configurations.

Key Considerations:

- DPW's Fabricated idlers are designed for long-term, reliable operation, often with features like lifetime lubrication and wear-resistant components.

Reduced Rolling Resistance: - Precision manufacturing and quality components minimize rolling resistance, improving efficiency and reducing operating costs.

Interchangeability: - Many fabricated idlers are designed to be interchangeable with original equipment parts, simplifying maintenance and replacement.

Impact Resistance: - Impact idlers are specifically designed to absorb the force of heavy materials dropping onto the conveyor belt.

Wear Resistance: - Heat treatment and other processes enhance the wear resistance of idler components, extending their lifespan.

Get the latest price? We'll respond as soon as possible