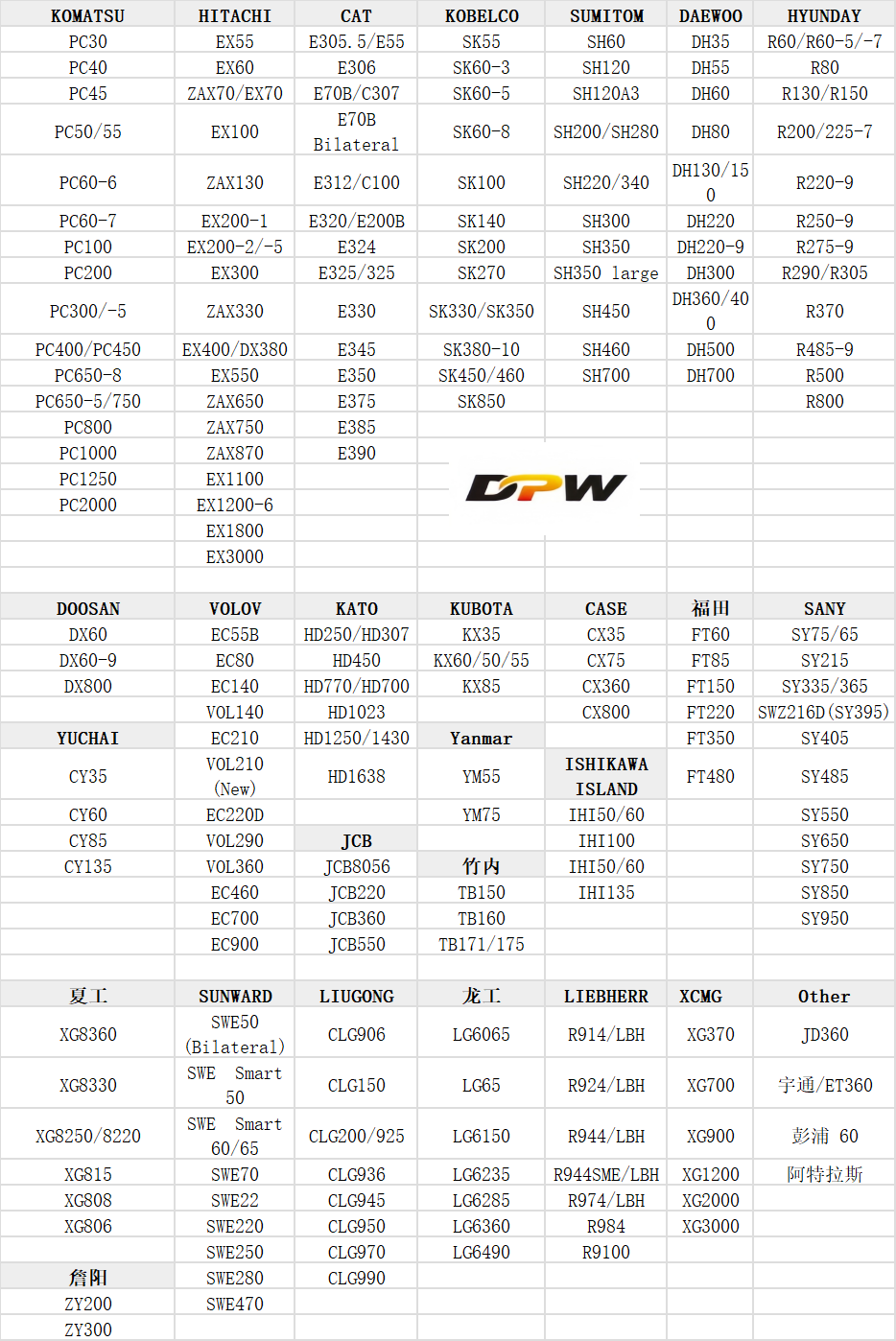

Komatsu front idler PC1000 (21N-30-13111)China idlers factories direct-/idlers manufacture-DPW/china excavator idler supply.

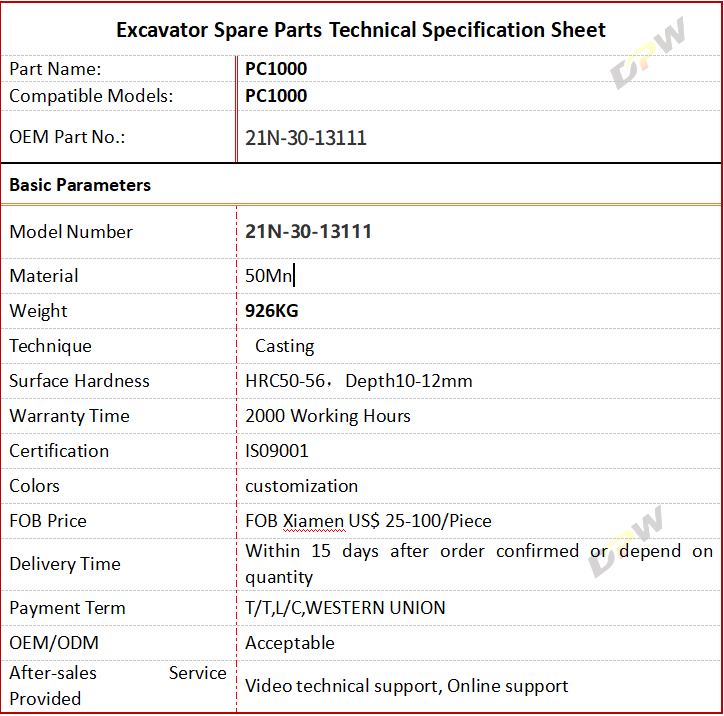

Product Specifications

Komatsu front idler PC1000 (21N-30-13111)China idlers factories direct-/idlers manufacture-DPW/china excavator idler supply.

Key Features & Benefits

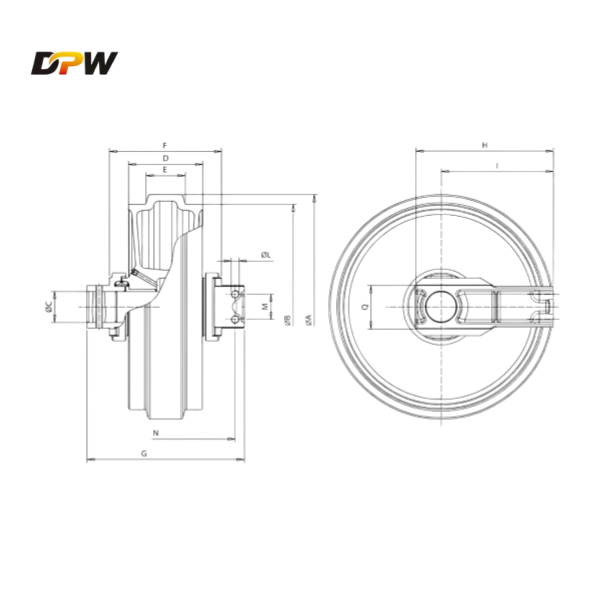

✔ High-Strength Cast Steel Construction – Durable and cost-effective for large mining excavators

✔ Reinforced Flange Design – Prevents track derailment under heavy loads

✔ Sealed & Lubricated Bearings – Extends service life in dusty/wet conditions

✔ OEM-Compliant Specifications – Exact fit for Komatsu PC1000-6/PC1000-8 models

✔ Optimized for Mining – Handles iron ore, copper, coal, and hard rock applications

Technical Specifications

| Parameter | Specification |

|---|---|

| Load Capacity | 45,000 kg (dynamic) |

| Bearing Type | Heavy-duty tapered roller bearings |

| Flange Thickness | 35mm (standard) |

| Material | High-carbon cast steel (HB 350-400) |

| Seal Type | Double-labyrinth + grease purge |

Compatible Models

Komatsu PC1000-6

Komatsu PC1000-8

Komatsu PC1100-6 (with adapter kits)

Why Choose Cast Idlers for PC1000?

✅ Proven Reliability – OEM-grade performance at competitive pricing

✅ Faster Availability – Shorter lead times vs. forged alternatives

✅ Balanced Cost-Efficiency – Ideal for standard mining operations

When to Replace Komatsu PC1000 Casting Idlers?

⚠ Flange wear >30% of original thickness

⚠ Cracks or spalling on roller surfaces

⚠ Bearing seizure or excessive play (>3mm)

⚠ Grease contamination/leakage

Maintenance Best Practices

Daily: Remove packed material from flanges

Weekly: Check bearing rotation smoothness

Monthly: Measure flange wear with calipers

Always: Replace in matched sets (minimum 3 rollers)

Available Configurations

Standard Duty (SD): For general mining/overburden

Enhanced Duty (ED): Hardened surface (+15% wear life)

With Wear Indicators: Laser-etched depth markers

Upgrade Options

▸ Tungsten Carbide Flange Overlays (+300% wear resistance)

▸ Telemetry Kits – Real-time wear monitoring

▸ Arctic Packages – -50°C rated seals

Need a Quote? Provide:

Your machine serial number

Current idler condition (photos welcome)

Primary material mined (e.g., iron ore, limestone)

Also available as part of complete Komatsu PC200/300/400/500/650/750/800/850/PC1000/1250/2000 undercarriage parts (sprockets + track chains + rollers).

DPW-PARTS:thounsands of parts for you to choose from,custmize various chassis parts according to customer needs