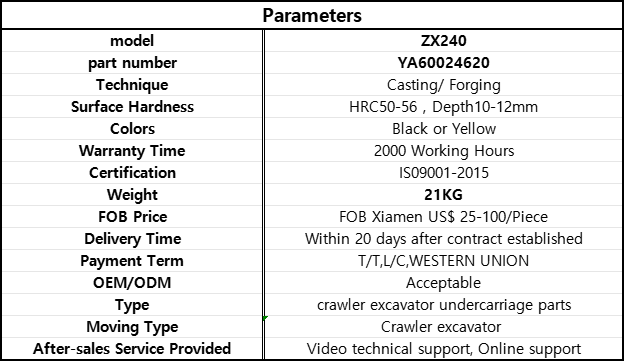

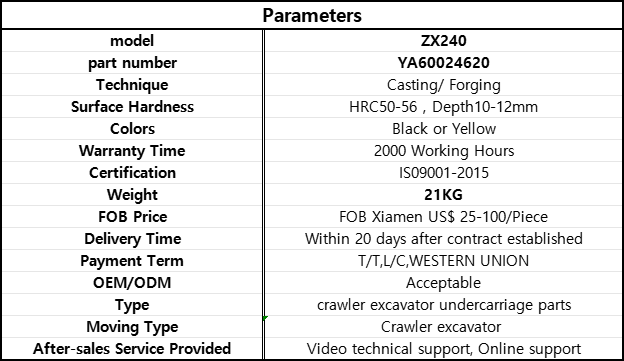

Hitachi excavator /YA60024620,ZX240-carrier/top roller assembly

Product Specifications

Hitachi excavator (YA60024620)-ZX240-carrier/top roller assembly-China carrier roller supply

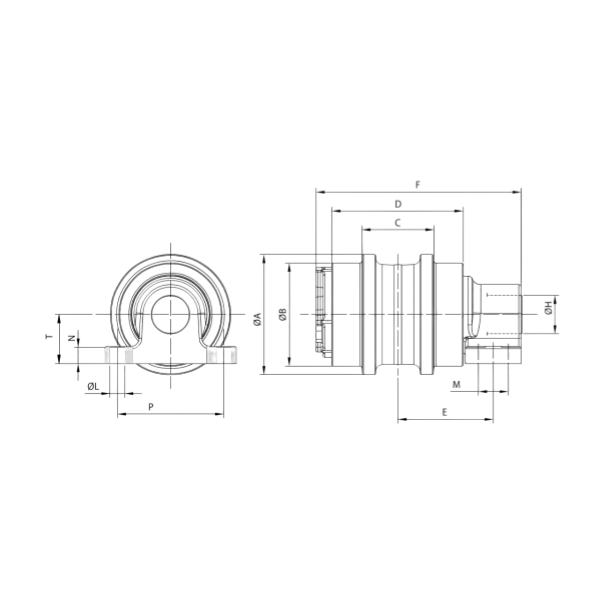

Excavator Carrier Roller: Overview & Key Details

The carrier roller (also called an upper roller) is a critical part of an excavator’s undercarriage system, supporting the weight of the machine and guiding the track chain along its path.

1. Functions of a Carrier Roller

- Supports Machine Weight: Helps distribute the excavator’s load evenly across the track.

- Guides the Track Chain: Keeps the track aligned and prevents lateral movement.

- Reduces Friction: Minimizes wear on the track links and other undercarriage components.

2. Types of Carrier Rollers

| Type | Description |

|---|---|

| Single-Flange | Has one raised edge to prevent track slippage (common in most excavators). |

| Double-Flange | Features flanges on both sides for extra track stability (used in high-stress conditions). |

| Non-Flanged | Smooth design, used in specific applications where lateral movement is minimal. |

| Sealed & Lubricated | Contains internal grease for longer lifespan (common in modern machines). |

3. Signs of a Worn-Out Carrier Roller

✔ Excessive Play or Wobble (bearing failure)

✔ Visible Wear or Flat Spots on the roller surface

✔ Track Misalignment or Derailment

✔ Grinding or Squeaking Noises while moving

✔ Grease Leaks (indicates seal damage)

Get the latest price? We'll respond as soon as possible